Introduction

Safety Signs

Controls

Operating

Replacement Parts

Service Machine Safely

Use Care In Handling and Servicing Batteries

Handling Waste Product and Chemicals

Service Utility Vehicle Safely

Service Interval Chart

Service Battery

Service Electrical

Service Miscellaneous

Troubleshooting

Storing Machine

Assembly

Specifications

Warranty

John Deere Service Literature

QUALITY DOESN'T END WHEN YOU INVEST IN A DEERE

CopyrightŠ Deere & Company

Service Machine Safely

Practice Safe Maintenance

ˇ Understand service procedure before doing work. Keep area clean and dry.

ˇ Never lubricate, service, or adjust vehicle while it is moving. Keep safety devices in place and in working condition. Keep hardware tight.

ˇ To prevent them from getting caught, keep hands, feet, clothing, jewelry, and long hair away from any moving parts.

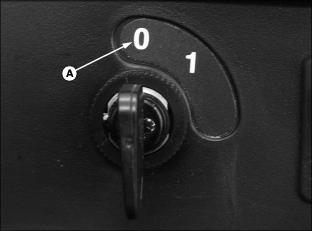

ˇ Turn key switch to the OFF "0" position.

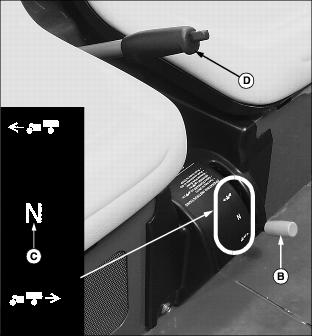

ˇ Move directional control lever to the NEUTRAL "N" position.

ˇ Move service/drive switch to the SERVICE position.

ˇ Securely support any vehicle elements that must be raised for service work.

ˇ Never support the vehicle in a raised position and run the motor.

ˇ Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or debris.

ˇ Disconnect battery set positive (B+) cable before servicing the electrical systems.

ˇ Unauthorized modifications to the vehicle may impair its function and safety.

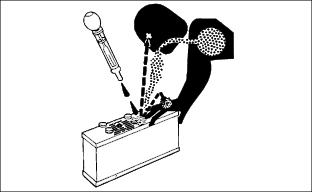

Use Care In Handling and Servicing Batteries

Prevent Battery Explosions

ˇ Batteries contain sulfuric acid and produce explosive mixtures of hydrogen. Because hydrogen gas is present even when the utility vehicle is not in operation, make sure batteries are stored and serviced in a well ventilated area.

ˇ Always wear proper eye, face and hand protection.

ˇ Keep sparks, lighted matches, and open flame away from the top of battery.

ˇ Remove all jewelry (watches, rings, bracelets, etc.) before servicing the electrical system or batteries.

ˇ Make sure work area is well ventilated.

ˇ Never lean over battery while testing or charging.

ˇ Keep removable vents tight and level except when servicing electrolyte.

ˇ Exercise caution while working with tools or conductors to prevent short circuits and sparks.

ˇ Never check battery charge by placing a metal object across the posts. Use a battery tester, voltmeter or hydrometer.

ˇ DO NOT charge a frozen battery; it may explode. Warm battery to 16°C (60°F).

Charging Safety

ˇ Never attempt to charge a battery set without first reviewing the instructions provided with the charger.

ˇ Use only the battery charger provided with the utility vehicle. DO NOT use substitutes.

ˇ Always wear proper eye, face and hand protection.

ˇ Keep sparks, lighted matches, and open flame away from the top of battery.

ˇ Make sure work area is well ventilated.

ˇ Never lean over battery while testing or charging.

ˇ Keep removable vents tight and level except when servicing electrolyte.

ˇ To avoid dangerous sparks, make sure the charger AC plug is disconnected before disconnecting the DC plug to the vehicle receptacle.

ˇ Never try to charge a visibly damaged or frozen battery.

ˇ Be sure that the key switch and all electrical accessories are turned off.

ˇ Make sure the charger leads are not broken, frayed or loose.

ˇ If the battery becomes hot, or if violent gassing or spewing of electrolyte occurs, unplug the charger AC source first before removing the DC plug.

ˇ If battery set is on charge, unplug the charger AC plug before disconnecting the charger DC cable plug to avoid dangerous sparks.

Prevent Acid Burns

Use extreme caution when handling electrolyte. Sulfuric acid in battery electrolyte is poisonous. It is strong enough to burn skin, eat holes in clothing, and cause blindness if splashed into eyes.

ˇ Filling batteries in a well-ventilated area.

ˇ Wearing eye and face protection, a rubber apron and rubber gloves.

ˇ Avoid breathing fumes when water is added.

ˇ Avoid spilling or dripping electrolyte.

ˇ If you spill acid on yourself:

ˇ Flush area of the body that has been exposed with water for at least 20 minutes.

ˇ Flush your eyes with clean, cool water for at least 20 minutes.

ˇ Remove contaminated clothing.

ˇ Get medical attention immediately.

ˇ Drink large amounts of water or milk. DO NOT induce vomiting.

ˇ Then drink milk of magnesia, beaten eggs, or vegetable oil.

ˇ Get medical attention immediately.

Using High Pressure Washers

Directing pressurized water at electronic/electrical components or connectors, bearings, or other sensitive parts and components may cause product malfunctions. Reduce water pressure if pressurized spray is used to clean the batteries and surrounding areas.

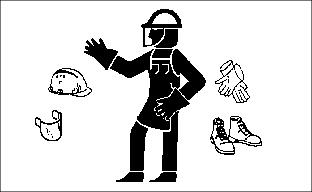

Wear Appropriate Clothing

ˇ Wear close fitting clothing and safety equipment appropriate for the job.

ˇ Loud noise can cause impairment or loss of hearing, wear a suitable protective device such as earplugs.

ˇ Do not wear radio or music headphones while servicing the machine. Safe service requires your full attention.

Handling Waste Product and Chemicals

ˇ Waste products such as batteries, can harm the environment and people.

ˇ DO NOT use beverage containers for waste fluids - someone may drink from them.

ˇ See your local Recycling Center or John Deere dealer to learn how to recycle or get rid of waste products.

ˇ A Material Safety Data Sheet (MSDS) provides specific details on chemical products: physical and health hazards, safety procedures, and emergency response techniques. The seller of the chemical products used with your vehicle is responsible for providing the MSDS for that product.

Service Utility Vehicle Safely

NOTE: The charger DC cable plug must be removed from the vehicle receptacle.

1. Turn key switch to the OFF "0" position (A).

2. Move directional control lever (B) to the NEUTRAL "N" position (C).

NOTE: Turn off all vehicle electric accessories.

5. Raise and tilt operator seat forward.

ˇ Move the service/drive switch (E) to the SERVICE position.

NOTE: The cargo box support rod should be removed and not used when the utility vehicle is equipped with a power lift option. The cargo box locks into whatever position the power lift mechanism is in.