Introduction

Safety

Controls

Operating

Replacement Parts

Service Machine Safely

Service Interval Chart

Service Engine

Service Transmission

Hydrostatic Transmission and Hydraulic Oil

Check Hydrostatic Transmission Oil Level

Change Hydrostatic Transmission Oil and Filter

Checking and Replacing Traction Drive Belt

Checking and Adjusting Transmission Neutral

Adjusting Control Lever Neutral Start Switches

Lubricate Traction Drive Belt Tensioner

Service Steering and Brakes

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Service Literature

John Deere Quality Statement

Copyright© Deere & Company

Service Transmission

Hydrostatic Transmission and Hydraulic Oil

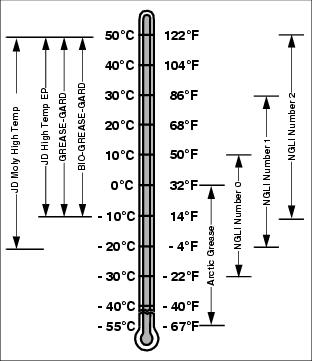

Use the following oil viscosity based on the air temperature range. Operating outside of the recommended oil air temperature range may cause premature hydrostatic transmission failure.

The following John Deere oil is PREFERRED:

Other oils may be used if they meet the following:

· API Service Classification SJ

Check Hydrostatic Transmission Oil Level

IMPORTANT: Avoid damage! Check oil level in reservoir tank when oil is cold. DO NOT overfill oil reservoir tank. Oil will expand during operation and could overflow. |

1. Park front mower on a level surface.

2. Stop engine and engage the park brake.

3. Lift and secure cowling in the open position.

4. Clean area around reservoir dipstick cap.

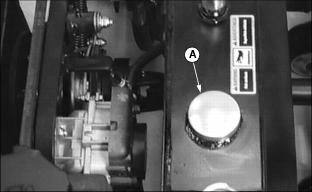

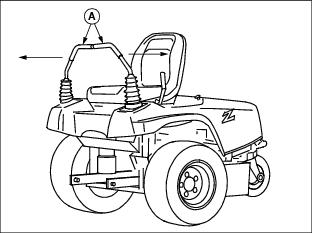

5. Turn and remove dipstick cap (A) from the oil reservoir tank.

7. Install dipstick cap but do not turn it.

8. Remove dipstick cap. Check oil level on dipstick.

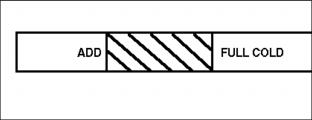

9. Oil must be between the ADD and FULL marks.

10. Add oil, if necessary. (See Hydrostatic Transmission and Hydraulic Oil in this section for the correct application.)

Change Hydrostatic Transmission Oil and Filter

1. Park front mower on a level surface.

2. Stop engine and engage the park brake. Allow engine and hydraulic oil reservoir to cool.

3. Lift and secure cowling in the open position.

4. Turn transmission oil filter (A) counterclockwise to remove. Allow transmission oil to drain into a drain pan with at least a 7.6 L (2.0 gal) capacity.

5. Apply a film of clean oil on gasket of new filter.

6. Install filter. Turn filter clockwise until gasket makes contact with the mounting surface. Tighten 1/2 to 3/4 turn after gasket contact.

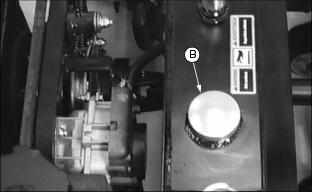

7. Clean area around reservoir dipstick cap.

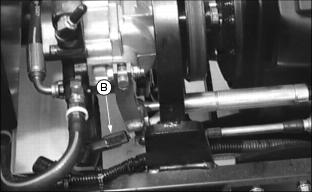

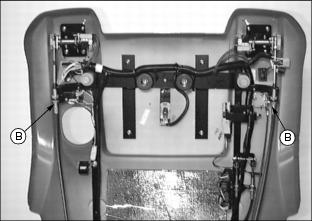

8. Turn and remove dipstick cap (B) from the oil reservoir tank.

9. Fill oil reservoir with approximately 7.6 L (2.0 gal) of oil. (See Hydrostatic Transmission and Hydraulic Oil in this section for the correct application.)

11. Move throttle lever to the FAST (r) position.

13. Cycle control levers forward and rearward several times. Check for leaks around filter.

14. Stop the engine. Check oil level. Add oil as necessary. (See Checking Hydraulic Oil Level in this section.)

Checking and Replacing Traction Drive Belt

NOTE: The transmission drive belt will not require a tension adjustment. Belt is self-adjusted using a spring tensioner.

Checking Belt:

1. Stop engine and engage the park brake.

2. Lift and secure cowling in the open position.

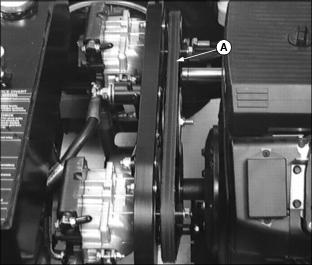

3. Inspect belt (A) for excessive wear, damage or stretching while in position on the transmission sheaves and drive belt tensioner pulley.

Replacing Belt

1. Disconnect PTO clutch electrical connection (B) located below the left steering pump.

NOTE: If deck is attached to the front mower, removal of mower deck PTO driveshaft from the clutch housing is required to complete this service procedure.

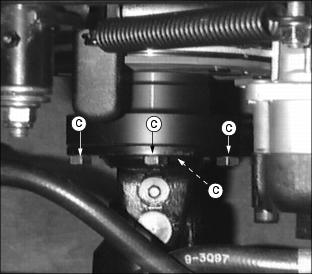

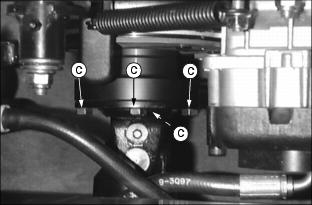

· Loosen and remove four hex bolts (C).

3. Disassemble the lower tether strap connection.

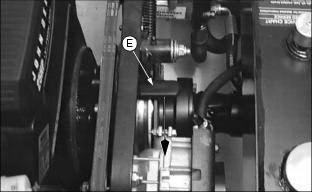

4. Stand on the right side of the front mower. Pull and hold spring loaded traction drive belt tensioner handle (E) rearward.

5. Remove belt from drive sheaves and idler pulley.

· Pull and hold traction drive belt tensioner handle.

· Install belt onto drive sheaves and idler pulley as shown.

· Release traction drive belt tensioner handle.

7. Install tether strap hardware.

· Align driveshaft mounting holes with the clutch mounting holes.

· Install four hex bolts (C). Tighten alternately.

9. Connect PTO clutch electrical connector.

Checking and Adjusting Transmission Neutral

· If it is necessary to run an engine in an enclosed area, use an exhaust pipe extension to remove the fumes. |

NOTE: Check and adjust transmission neutral with front mower parked on a level surface.

Check Adjustment:

· Set throttle lever to the 1/2 fast position.

· If drive wheels begin to creep, an adjustment is required.

Transmission Neutral Adjustment:

1. Stop engine and engage park brake.

2. Remove mower deck from front mower. (See Removing Mower Deck in the mower deck operator's manual.)

3. Elevate front mower with a safe lifting device, wood blocks or jackstands.

· Drive wheels must have the ability to rotate freely.

· Drive wheels may be removed for better access to the transmission.

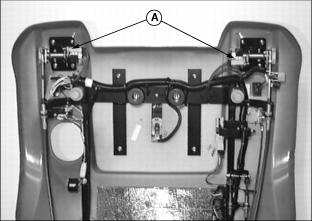

4. Move control levers (A) to the swing-out neutral position.

5. Raise and secure cowling in the open position.

6. Locate both steering control cables (B) behind the front mower cowling.

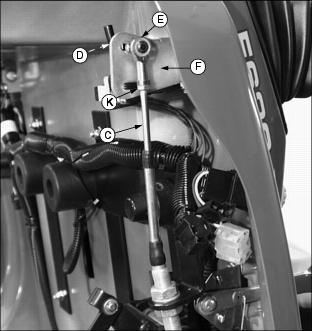

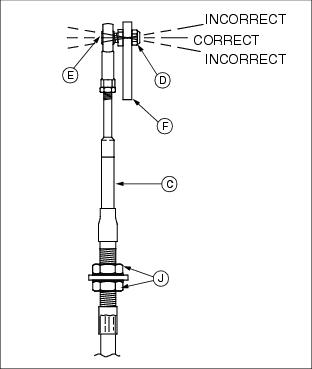

7. Disconnect left and right steering cable rod ends (C).

· Loosen and remove locknut (D).

· Remove steering cable eyebolts (E) from slotted control arm plates (F).

8. Depress bottom of operator seat to activate seat safety switch or use a jumper wire to bypass the seat switch circuit.

9. Start engine. Release park brake lever.

· If drive wheels continue to creep, a transmission drive pump dampener adjustment is required.

· If no drive wheel creep is detected, bypass the drive pump dampener adjustment and proceed to the control cable adjustment.

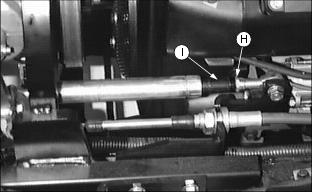

Adjust Transmission Drive Pump Dampeners:

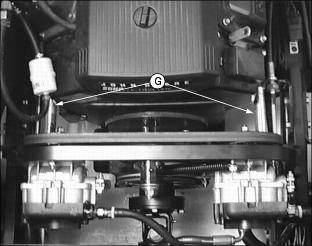

1. Locate left and right transmission drive pump dampeners (G).

· Rotate each inner dampener cylinder (I) until creep is gone.

· Continue to adjust dampener until creep is gone.

Adjust Control Cables:

1. Loosen control cable jam nuts (J) on each steering cable.

NOTE: Eyebolts should be installed and tightened to the bottom of each slotted control arm plate.

2. Adjust cable rod ends (C) up or down until steering cable eyebolts (E) can be inserted absolutely perpendicular inside the slotted control arm plates (F).

3. Tighten control cable jam nuts (J).

4. Install and tighten lock nuts (D).

5. Check adjustment. If further adjustment is required, repeat steps 1-4.

6. Stop engine. Lower cowling.

7. Check front mower tracking adjustment. (See Adjust Tracking in the Service Steering & Brakes section.)

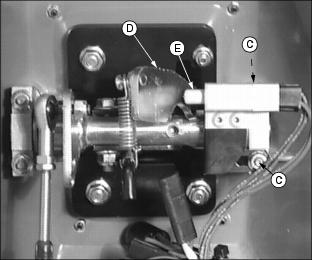

Adjusting Control Lever Neutral Start Switches

Both control lever neutral safety switch positions (A) are adjustable if necessary.

Test Neutral Start Switches

1. Park front mower on a level surface.

3. Raise and secure cowling in the open position.

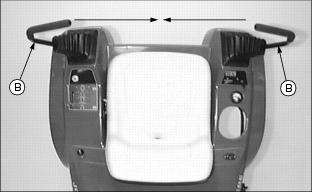

5. Slowly move both control levers (B) inward to a centered neutral position.

· If properly adjusted, the engine should kill.

· If the engine continues to run, a neutral start switch adjustment will be needed.

Adjust Neutral Start Switch Position

2. Loosen two lock nuts (C) attaching neutral start switch to bottom of cowling.

3. Slide switch in slotted channel until neutral detent plate (D) makes contact with the switch plunger (E).

5. Repeat procedure for other switch.

Grease

Use grease based on the expected air temperature range during the service interval.

The following greases are preferred:

· John Deere Moly High Temperature EP Grease.

· John Deere High Temperature EP Grease.

Other greases may be used are:

· SAE Multipurpose EP Grease with 3 to 5 percent molybdenum disulfide.

· Greases meeting Military Specification MIL-G-10924C may be used as arctic grease.

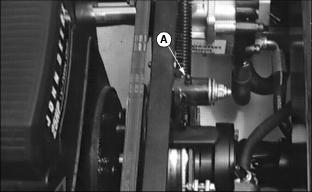

Lubricate Traction Drive Belt Tensioner

1. Stop engine and engage the park brake.

2. Lift and secure cowling in the open position.

3. Lubricate idler arm grease fitting (A). (See Grease in this section for the proper application.)