Introduction

Product Identification

Safety

Operating

Replacement Parts

Service Intervals

Service Engine

Service Transmission

Service - Hydraulics

Changing the Hydraulic Oil and Filter

Clean Hydraulic Oil Reservoir Strainer

Service Steering & Brakes

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

Service Record

Copyright© Deere & Company

Service - Hydraulics

Hydraulic Oil

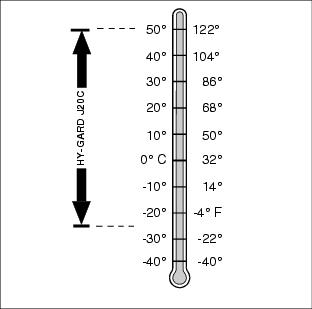

Use oil viscosity based on the expected air temperature range during the period between oil changes.

The following John Deere transmission and hydraulic oil is preferred:

Check Hydraulic Oil Level

NOTE: This service procedure should be performed on vehicles equipped with the auxiliary hydraulic kit.

IMPORTANT: Avoid damage! Check oil level in reservoir tank when oil is cold. Do not overfill oil reservoir tank. Oil will expand during operation and could overflow. |

1. Raise attachment to service position. (See Using the Lift Cylinder Safety Support in the Safety section.)

2. Park vehicle safely. (See Parking Safely in the Safety section.)

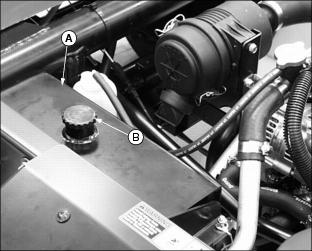

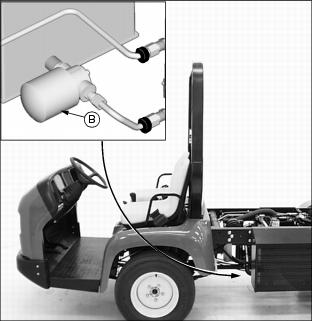

3. Locate auxiliary oil reservoir (A) on left side of vehicle.

4. Thoroughly clean area around dipstick cap (B).

5. Remove dipstick cap (B) from the oil reservoir tank. Visually check level of oil.

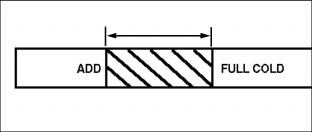

· Oil must be between the "ADD" and "FULL COLD" marks on the dipstick.

7. Install and tighten dipstick cap.

Changing the Hydraulic Oil and Filter

NOTE: This service procedure should be performed on vehicles equipped with the auxiliary hydraulic kit.

1. Raise attachment to service position. (See Using the Lift Cylinder Safety Support in the Safety section.)

2. Park vehicle safely. (See Parking Safely in the Safety section.)

· Allow the engine and the oil reservoir to cool.

3. Locate drain plug (A) under the oil reservoir on the left side of the vehicle.

4. Place container under the oil drain location.

5. Remove drain plug. Allow oil to drain into a container with at least a 13.2 L (3.5 gal) capacity.

6. Remove hydraulic oil filter (B).

· Locate filter left side of vehicle when hydraulic kit is installed.

· Locate filter on base unit machine in the center of vehicle, directly behind control valve.

7. Turn filter counterclockwise to remove. Use a drain pan to catch dripping oil.

8. Apply a film of clean oil on gasket of new filter.

9. Turn filter clockwise until gasket makes contact with the mounting surface. Tighten 1/2 to 3/4 turn after gasket contact.

10. Install drain plug. Do not overtighten.

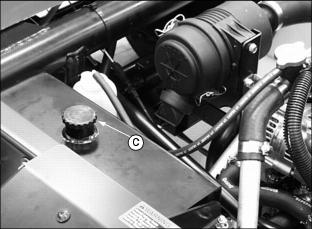

11. Thoroughly clean area around dipstick cap (C).

12. Remove dipstick cap from the oil reservoir tank.

13. Fill oil reservoir with approximately 13.2 L (3.5 gal) of oil.

15. Cycle the hydraulic PTO lever (D) for approximately one or two minutes. Check for leaks.

17. Check oil level. Add oil as necessary.

18. Lower attachment or cargo box.

Clean Hydraulic Oil Reservoir Strainer

NOTE: This service procedure should be performed on vehicles equipped with auxiliary hydraulic kit.

Routinely clean strainer when changing the hydraulic oil and filter. Strainer should be serviced when the hydraulic oil tank is empty.

1. Change hydraulic oil and filter.

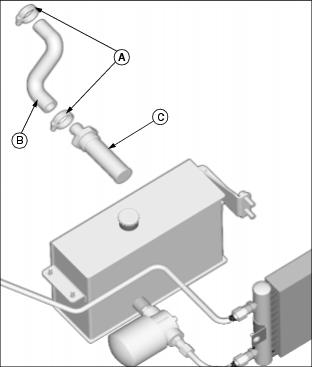

2. Loosen adjustable hose clamp (A).

3. Remove rubber hose (B) from strainer (C).

4. Remove strainer from the hydraulic oil tank.

5. Clean strainer with solvent or mineral spirits and allow to dry.

6. Install strainer into the hydraulic oil tank.

7. Install rubber hose onto strainer.

8. Tighten adjustable hose clamp.

Cleaning Oil Cooling Coils

NOTE: This service procedure should be performed on vehicles equipped with auxiliary hydraulic kit.

1. Raise attachment to service position.(See Using the Lift Cylinder Safety Support in the Safety section.)

2. Park vehicle safely. (See Parking Safely in the Safety section.)

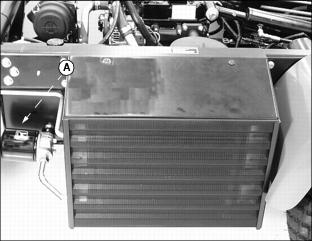

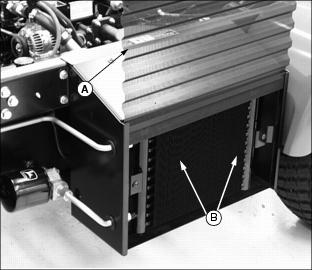

3. Lift air intake screen (A) from position in front of the engine radiator.

4. Remove dirt and debris from the oil cooling coils (B) using compressed air or water. Check coils for damage.