Specifications

Engine

Model

Yanmar

|

Engine Model Number

|

3TG72UJF

|

Horsepower

|

20.8 kW (28 hp)

|

Cylinders

|

3

|

Stroke

|

72 mm (2.84 in.)

|

Cycle

|

4

|

Displacement

|

879 cm3 (53.6 cu. in.)

|

Bore

|

72 mm (2.84 in.)

|

Compression Ratio

|

8.7-1

|

Speed (fast idle), no load

|

3400 rpm

|

Speed (slow idle), no load

|

1700 rpm

|

Lubrication System

|

Pressure Fed

|

Oil Filter

|

Full Flow, Replaceable

|

Air Cleaner

|

Replaceable with pre-cleaner

|

Max.Torque (ft/lb)

|

41 @ 3600 rpm

|

Crankshaft Alignment

|

Horizontal

|

Ignition

|

Electronic transistor

|

Starter

|

Positive engagement

|

Engine (Continued)

Starting System

|

0.8 kW (12 volt)

|

Choke

|

Semi-Automatic

|

Governor

|

Mechanical

|

Engine Oil Capacity

|

3.2 L (3.5 U.S. qt.) With Filter

|

Cooling System

|

Liquid-Cooled

|

Cooling System Capacity

|

4.93 L (5.25 U.S. qt.)

|

Fuel System

Fuel

|

Regular unleaded gasoline

|

Fuel Tank Location

|

Right and Left Side

|

Capacity

|

41.6 L (11 U.S. gal.)

|

Carburetor Type

|

Downdraft with Manual Choke

|

Fuel Filter

|

Paper Element

|

Fuel Pump

|

Electric

|

Fuel Pump Location

|

Frame

|

Drive Train

Transmission

|

Hydrostatic U-Type

|

Manufacturer

|

Sundstrand

|

No. of Speeds

|

Infinite

|

Travel Speeds:

· Forward

· Reverse

|

17.0 km/h (10.6 mph)

8.5 km/h (5.3 mph)

|

Drive Train (Continued)

Differential Lock

|

Standard

|

Gear Ratio

|

20.41:1

|

Capacity

|

4.6 U.S. qt (4.4 L)

|

Transmission Oil Cooler

|

Radiator type

|

Speed/Direction Control

|

2-Pedal foot control

|

Cruise Control

|

Standard

|

PTO Clutch

|

Electric

|

Tires

Drive

|

23 x 8.5 - 12, 4 PR, Turf

|

Steering

|

16 x 16.5 - 8, 4 PR, Rib

|

Steering

Brakes

Type

|

Independent, sealed drum,

automotive type

|

Size

|

178 mm (7 in.)

|

Location

|

Front drive tires

|

Power Take Off

Type

|

Electric Coupler

|

Drive

|

1 in. shaft with two belts

|

Speed

|

2396 @ 3450 engine rpm

|

Shaft Rotation

|

Counter clockwise when facing PTO shaft

|

Noise Level (dBa)

Without Mower

|

82.4; 82.8

|

With 60-inch Mower

|

88.4; 88.3

|

With 72-inch Mower

|

90.5; 90.4

|

Weight

Shipping (approx.)

|

659 kg (1483 lb.)

|

Electrical

Charging System

|

Automotive Type

|

Alternator

|

40 amp

|

Battery Voltage

|

12

|

Reserve Capacity

|

102 min. @ 25 amp

|

Cold Cranking amp @ 0°F

|

491 amp

|

Dimensions

Overall Height to Top of Steering Wheel

|

1.35 m (53.5 in.)

|

Overall Height to Top of Hood

|

.97 m (38.5 in.)

|

Overall Height With ROPS

|

2.0 m (81.0 in.)

|

Overall Width

|

1.09 m (42.8 in.)

|

Overall Length:

· With 60-Inch Mower

· With 72-Inch Mower

|

2.16 m (85.2 in.)

2.87 m (112.9 in.)

2.93 m (122.5 in.)

|

Ground Clearance

|

165 mm (6.5 in.)

|

Wheelbase

|

1.43 m (56.3 in.)

|

Min. Turn Radius Without Brakes:

· L.H.

· R.H.

|

445 mm (17.5 in.)

737 mm (29 in.)

|

MIn. Turn Radius With Brakes:

· L.H. and R.H.

|

0

|

Recommended Lubricants

Engine Oil

|

John Deere PLUS-4®

|

Transmission Oil

|

John Deere Low Viscosity HY-GARD (J20D)

|

Engine Coolant

|

Ethylene Glycol Base

|

Grease

|

John Deere MOLY HIGH TEMPERATURE EP GREASE

John Deere HIGH TEMPERATURE EP GREASE

John Deere GREASE-GARDTM

|

Hydrostatic Drive Oil

|

John Deere HY-GARD®

John Deere Low Viscosity HI-GARD ®

|

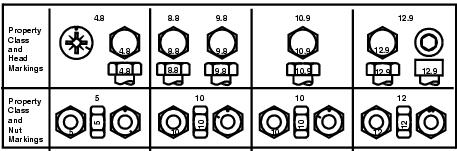

Metric Bolt and Cap Screw Torque Values

|

Class 4.8

|

Class 8.8 or 9.8

|

|

Lubricateda

|

Drya

|

Lubricateda

|

Drya

|

Size

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

M6

|

48

|

3.5

|

6

|

4.5

|

9

|

6.5

|

11

|

8.5

|

M8

|

12

|

8.5

|

15

|

11

|

22

|

16

|

28

|

20

|

M10

|

23

|

17

|

29

|

21

|

43

|

32

|

55

|

40

|

M12

|

40

|

29

|

50

|

37

|

75

|

55

|

95

|

70

|

M14

|

63

|

47

|

80

|

60

|

120

|

88

|

150

|

110

|

M16

|

100

|

73

|

125

|

92

|

190

|

140

|

240

|

175

|

M18

|

135

|

100

|

175

|

125

|

260

|

195

|

330

|

250

|

M20

|

190

|

140

|

240

|

180

|

375

|

275

|

475

|

350

|

M22

|

260

|

190

|

330

|

250

|

510

|

375

|

650

|

475

|

M24

|

330

|

250

|

425

|

310

|

650

|

475

|

825

|

600

|

M27

|

490

|

360

|

625

|

450

|

950

|

700

|

1200

|

875

|

M30

|

675

|

490

|

850

|

625

|

1300

|

950

|

1650

|

1200

|

M33

|

900

|

675

|

1150

|

850

|

1750

|

1300

|

2200

|

1650

|

M36

|

1150

|

850

|

1450

|

1075

|

2250

|

1650

|

2850

|

2100

|

Metric Bolt and Cap Screw Torque Values (Continued)

|

Class 10.9

|

Class 12.9

|

|

Lubricateda

|

Drya

|

Lubricateda

|

Drya

|

Size

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

M6

|

13

|

9.5

|

17

|

12

|

15

|

11.5

|

19

|

14.5

|

M8

|

32

|

24

|

40

|

30

|

37

|

28

|

47

|

35

|

M10

|

63

|

47

|

80

|

60

|

75

|

55

|

95

|

70

|

M12

|

110

|

80

|

140

|

105

|

130

|

95

|

165

|

120

|

M14

|

175

|

130

|

225

|

165

|

205

|

150

|

260

|

109

|

M16

|

275

|

200

|

350

|

225

|

320

|

240

|

400

|

300

|

M18

|

375

|

275

|

475

|

350

|

440

|

325

|

560

|

410

|

M20

|

530

|

400

|

675

|

500

|

625

|

460

|

800

|

580

|

M22

|

725

|

540

|

925

|

675

|

850

|

625

|

1075

|

800

|

M24

|

925

|

675

|

1150

|

850

|

1075

|

800

|

1350

|

1000

|

M27

|

1350

|

1000

|

1700

|

1250

|

1600

|

1150

|

2000

|

1500

|

M30

|

1850

|

1350

|

2300

|

1700

|

2150

|

1600

|

2700

|

2000

|

M33

|

2500

|

1850

|

3150

|

2350

|

2900

|

2150

|

3700

|

2750

|

M36

|

3200

|

2350

|

4050

|

3000

|

3750

|

2750

|

4750

|

3500

|

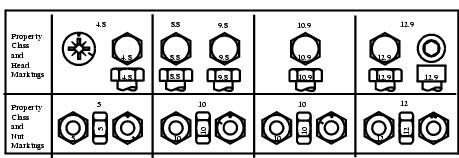

Metric Bolt and Cap Screw Torque Values (Continued)

DO NOT use these values if a different torque value or tightening procedure is given for a specific application. Torque values listed are for general use only. Check tightness of fasteners periodically.

Shear bolts are designed to fail under predetermined loads. Always replace shear bolts with identical grade.

Fasteners should be replaced with the same or higher grade. If higher grade fasteners are used, these should only be tightened to the strength of the original. Make sure fasteners threads are clean and that you properly start thread engagement. This will prevent them from failing when tightening.

Tighten plastic insert or crimped steel-type lock nuts to approximately 50 percent of the dry torque shown in the chart, applied to the nut, not to the bolt head. Tighten toothed or serrated-type lock nuts to the full torque value.

a "Lubricated" means coated with a lubricant such as engine oil, or fasteners with phosphate and oil coatings. "Dry" means plain or zinc plated without any lubrication.

b Grade 2 applies for hex cap screws (not hex bolts) up to 152 mm (6-in) long. Grade 1 applies for hex cap screws over 152 mm (6-in) long, and for all other types of bolts and screws of any length.

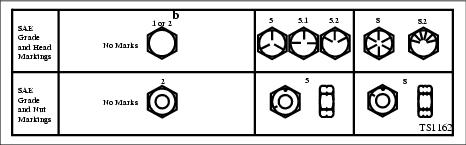

Unified Inch Bolt and Cap Screw Torque Values

|

Grade 1

|

Grade 2b

|

|

Lubricateda

|

Drya

|

Lubricateda

|

Drya

|

SIZE

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

1/4

|

3.7

|

2.8

|

4.7

|

3.5

|

6

|

4.5

|

7.5

|

5.5

|

5/16

|

7.7

|

5.5

|

10

|

7

|

12

|

9

|

15

|

11

|

3/8

|

14

|

10

|

17

|

13

|

22

|

16

|

27

|

20

|

7/16

|

22

|

16

|

28

|

20

|

35

|

26

|

44

|

32

|

1/2

|

33

|

25

|

42

|

31

|

53

|

39

|

67

|

50

|

9/16

|

48

|

36

|

60

|

45

|

75

|

56

|

95

|

70

|

5/8

|

67

|

50

|

85

|

62

|

105

|

78

|

135

|

100

|

3/4

|

120

|

87

|

150

|

110

|

190

|

140

|

240

|

175

|

7/8

|

190

|

140

|

240

|

175

|

190

|

140

|

240

|

175

|

1

|

290

|

210

|

360

|

270

|

290

|

210

|

360

|

270

|

1-1/8

|

470

|

300

|

510

|

375

|

470

|

300

|

510

|

375

|

1-1/4

|

570

|

425

|

725

|

530

|

570

|

425

|

725

|

530

|

1-3/8

|

750

|

550

|

950

|

700

|

750

|

550

|

950

|

700

|

1-1/2

|

1000

|

725

|

1250

|

925

|

990

|

725

|

1250

|

930

|

Unified Inch Bolt and Cap Screw Torque Values (Continued)

|

Grade 5, 5.1 or 5.2

|

Grade 8 or 8.2

|

|

Lubricateda

|

Drya

|

Lubricateda

|

Drya

|

SIZE

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

1/4

|

9.5

|

7

|

12

|

9

|

13.5

|

10

|

17

|

12.5

|

5/16

|

20

|

15

|

25

|

18

|

28

|

21

|

35

|

26

|

3/8

|

35

|

26

|

44

|

33

|

50

|

36

|

63

|

46

|

7/16

|

55

|

41

|

70

|

52

|

80

|

58

|

100

|

75

|

1/2

|

85

|

63

|

110

|

80

|

120

|

90

|

150

|

115

|

9/16

|

125

|

90

|

155

|

115

|

175

|

130

|

225

|

160

|

5/8

|

170

|

125

|

215

|

160

|

215

|

160

|

300

|

225

|

3/4

|

300

|

225

|

375

|

280

|

425

|

310

|

550

|

400

|

7/8

|

490

|

360

|

625

|

450

|

700

|

500

|

875

|

650

|

1

|

725

|

540

|

925

|

675

|

1050

|

750

|

1300

|

975

|

1-1/8

|

900

|

675

|

1150

|

850

|

1450

|

1075

|

1850

|

1350

|

1-1/4

|

1300

|

950

|

1650

|

1200

|

2050

|

1500

|

2600

|

1950

|

1-3/8

|

1700

|

1250

|

2150

|

1550

|

2700

|

2000

|

3400

|

2550

|

1-1/2

|

2250

|

1650

|

2850

|

2100

|

3600

|

2650

|

4550

|

3350

|

Unified Inch Bolt and Cap Screw Torque Values (Continued)

DO NOT use these values if a different torque value or tightening procedure is given for a specific application. Torque values listed are for general use only. Check tightness of fasteners periodically.

Shear bolts are designed to fail under predetermined loads. Always replace shear bolts with identical grade.

Fasteners should be replaced with the same or higher grade. If higher grade fasteners are used, these should only be tightened to the strength of the original. Make sure fasteners threads are clean and that you properly start thread engagement. This will prevent them from failing when tightening. Tighten plastic insert or crimped steel-type lock nuts to approximately 50 percent of the dry torque shown in the chart, applied to the nut, not to the bolt head.

Tighten toothed or serrated-type lock nuts to the full torque value.

a "Lubricated" means coated with a lubricant such as engine oil, or fasteners with phosphate and oil coatings. "Dry" means plain or zinc plated without any lubrication.

b Grade 2 applies for hex cap screws (not hex bolts) up to 152 mm (6-in.) long. Grade 1 applies for hex cap screws over 152 mm (6-in.) long, and for all other types of bolts and screws of any length.

|