M653, M655 and M665 PIN (010001- )

Introduction

Safety Signs

Controls

Operating Machine

Replacement Parts

Service Machine Safely

Service Interval Chart

Service Lubrication

Service Engine

Service Transmission

Service Steering & Brakes

Service Mower

Service Electrical

Service Miscellaneous

Tightening Drive Wheel Hardware

Troubleshooting

Storing Machine

Assembly

Specifications

Warranty

John Deere Service Literature

John Deere Quality Statement

CopyrightŠ Deere & Company

Service Miscellaneous

Checking Tire Pressure

2. Check tire pressure with an accurate gauge.

Fuel

IMPORTANT: Avoid damage! Avoid spilling fuel. Fuel can damage plastic and painted surfaces. DO NOT mix oil with gasoline. Unleaded gasoline with an octane rating of 87 or higher is recommended. |

ˇ Use only clean, fresh, unleaded regular grade gasoline.

ˇ Remove any trash from top of fuel tank drain area.

ˇ Use summer blended fuel for warm weather operation and winter blended fuel for cold weather.

ˇ Never use fuel that is stale or has been stored for a long period of time:

Warm Weather - Maximum 60 days.

Cold Weather - Maximum of 90 days.

ˇ Fill fuel tank at the end of each day's operation. This helps to keep condensation out of fuel tank.

Oxygenated Fuel

Oxygenates (either ethanol or MTBE) are added to the gasoline. If you use the oxygenated fuel be sure it is unleaded and meets the minimum octane rating requirement.

The following are the EPA approved percentages of fuel oxygenates:

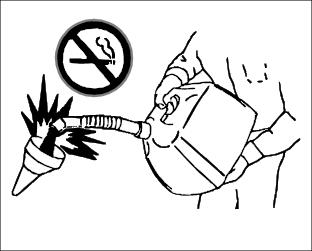

Filling Fuel Tanks

NOTE: Fuel capacity of both saddle tanks is 34L (10 gal) or 17.0 L (5.0 gal) each.

1. STOP engine. If engine is hot let it cool several minutes before adding fuel.

3. Fill tank 25 mm (1 in.) below bottom of filler neck.

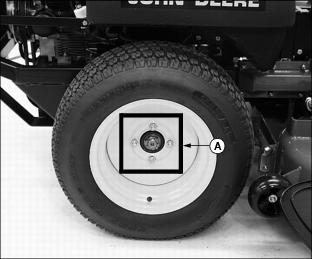

Tightening Drive Wheel Hardware

NOTE: Tighten nuts after first 5 hours of operation and every 50 hours thereafter.

ˇ Tighten rear drive wheel nuts (A) alternately to 100 Nˇm (75 lb-ft.).

Care for Painted Surfaces

Correct Cleaning Care:

Follow automotive practices to care for your machine painted metal surfaces. Use a high-quality automotive wax regularly to maintain the factory look of your tractor's painted surfaces.

Repair-Minor Surface Scratches:

1. Clean area thoroughly to be repaired.

2. Use automotive polishing compound to remove surface scratches.

ˇ DO NOT use rubbing compound to avoid removing paint.

3. Apply wax to entire surface.

Repair-Deep Scratches (Bare Metal or Primer Showing):

1. Clean area to be repaired with rubbing alcohol or mineral spirits.

2. Use paint stick with factory-matched colors available from your John Deere dealer to fill scratches. Follow directions for use and for drying.

ˇ Apply sparingly to scratch without getting on surrounding painted surface. Fill in scratch to level of surrounding painted area.

ˇ Allow to dry 48 hours in warm weather and up to 30 days in colder temperatures.

3. Use automotive polishing compound to smooth out surface. Do not use power buffer.