Introduction

Safety Labels

Controls

Operating - Machine

Operating - Cutting Units

Service Safely

Service Interval Chart

Service Lubrication

Service Engine

Engine Warranty Maintenance Statement

Adjusting Throttle Lever Location

Adjusting Throttle Lever Tension

Cleaning Spark Plug And Adjusting Electrode Gap

Service - Cutting Units

Service - Belts

Troubleshooting

Storing Machine

Assembly

Specifications

Warranty

John Deere Quality Statement

Copyright© Deere & Company

Service Engine

Engine Warranty Maintenance Statement

Maintenance, repair, or replacement of the emission control devices and systems on this engine, which are being done at the customers expense, may be performed by any nonroad engine repair establishment or individual. Warranty repairs must be performed by an authorized John Deere dealer.

Avoid Fumes

· If it is necessary to run an engine in an enclosed area, use an exhaust pipe extension to remove the fumes. |

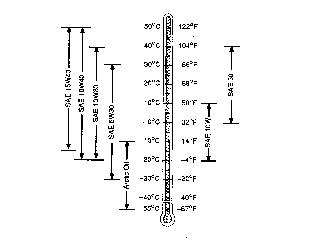

Use oil viscosity based on the expected air temperature range during the period between oil changes.

The following oil is preferred:

Other oils may be used if they meet one of the following:

· API Service Classification SG

· API Service Classification SF

Oils meeting Military Specification MIL-L-46167B may be used as arctic oils.

IMPORTANT: Avoid damage! Avoid spilling fuel. Fuel can damage plastic and painted surfaces. DO NOT mix oil with gasoline. Unleaded gasoline with an octane rating of 87 or higher is recommended. |

· Use only clean, fresh, unleaded regular grade gasoline.

· Remove any trash from top of fuel tank drain area.

· Never use fuel that is stale or has been stored for a long period of time:

Warm Weather: Maximum 60 days.

Cold Weather: Maximum of 90 days.

· Fill fuel tank at the end of each day's operation. This helps to keep condensation out of fuel tank.

Oxygenates (either ethanol or MTBE) are added to the gasoline. If you use the oxygenated fuel be sure it is unleaded and meets the minimum octane rating requirement.

The following are the EPA approved percentages of fuel oxygenates:

ETHANOL (Ethyl or Grain Alcohol): You may use gasoline containing up to 10 percent ethanol by volume.

MTBE (Methyl Tertiary Butyl Ether): You may use gasoline containing up to 15 percent MTBE by volume.

METHANOL (Methyl or Wood Alcohol): You may use gasoline containing up to 5 percent methanol by volume, as long as it also contains cosolvents and corrosion inhibitors to protect the fuel system. Gasoline containing more than 5 percent methanol by volume may cause starting and/or performance problems. It may also damage metal, rubber, and plastic parts of your fuel system.

Filling Fuel Tank (Continued)

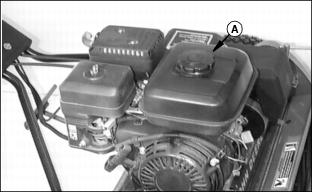

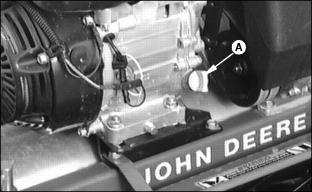

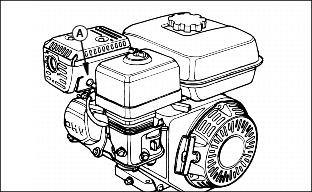

1. Wipe dust and dirt from around fuel cap (A) and remove cap.

2. Fill fuel tank at the end of each day's operation:

· Fill to bottom of filler neck to allow room for gas to expand.

· Fuel tank capacity: 2.5 L

(2.6 U.S. qt).

· Install fuel tank cap and tighten.

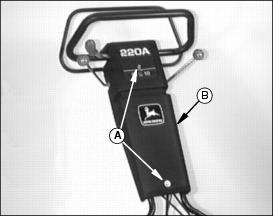

Adjusting Throttle Lever Location

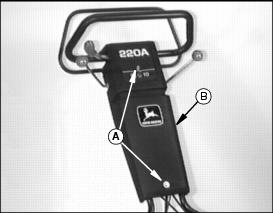

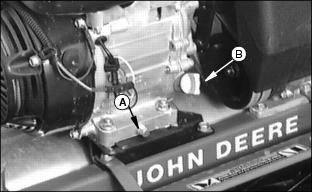

1. Remove two bolts (A) (10 mm).

2. Remove handlebar cover (B).

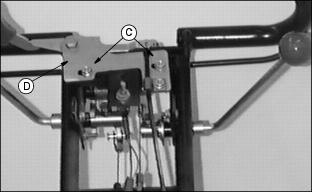

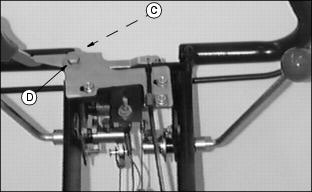

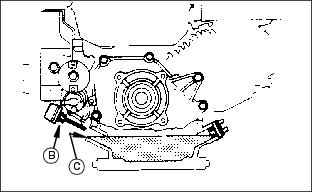

3. Loosen two nuts (C) (10 mm).

4. Move throttle lever plate (D) to where the throttle lever location is most comfortable to the operator.

6. Install handlebar cover with two bolts and tighten.

Adjusting Throttle Lever Tension

1. Remove two bolts (A) (10 mm).

2. Remove handlebar cover (B).

3. Using two wrenches, tighten or loosen the lock nut (C) on the throttle pivot bolt (D). At the proper tension, the throttle lever is easy to move, yet maintains the desired throttle setting during operation.

4. Install handlebar cover with two bolts and tighten.

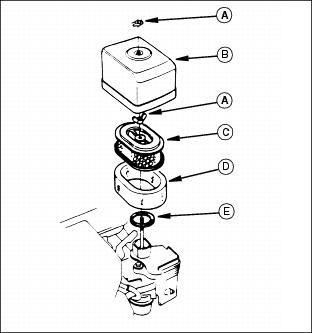

Cleaning Air Cleaner

NOTE: Clean and oil every 25 hours under normal conditions. If used under very dusty conditions, clean once a day or every ten hours.

1. Remove wing nut (A) to remove air cleaner cover (B).

2. Remove second wing nut (A) to remove air cleaner element (C) and precleaner (D).

3. Check housing, precleaner, element and rubber gasket (E) for damage. Housing must seat well and permit only filtered air to reach carburetor. Replace if necessary.

4. Be sure nothing is obstructing the air passage.

5. Precleaner (D) - Clean every 25 hours of operation:

· Wash in detergent and water, rinse in clean water.

· Saturate in clean engine oil and squeeze out excess.

· Air cleaner element (C) - Clean or replace every 100 hours of operation:

· If element is dirty, tap gently on your hand to remove dust.

· If element is extremely dirty or damaged, install new element.

· Assemble air cleaner assembly and install two wing nuts.

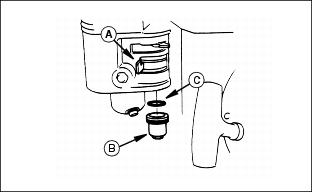

Cleaning Fuel Sediment Bowl

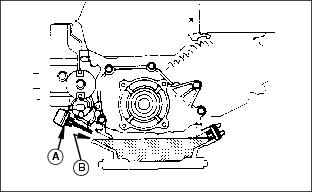

1. Turn fuel shut-off valve (A) to the OFF position.

2. Unscrew and remove sediment bowl (B) and O-ring (C).

3. Clean thoroughly with John Deere degreasing solvent or equivalent.

Checking Engine Oil Level

1. Be sure engine is in a level position, if necessary, put a block under front roller to level engine.

NOTE: Do not screw dipstick into engine to check oil level.

2. Remove dipstick (A), wipe clean, and insert into filler port.

3. If no oil or only a slight amount is seen, add to full level (B). Do not overflow.(See Engine Oil in this section for correct oil.)

Oil capacity: 0.6 L (0.6 U.S. qt).

4. Wipe any spilled oil off mower.

Changing Engine Oil

NOTE: Change engine oil after first 20 hours of operation, then every 50 hours. Check and fill plugs are located in front and rear of machine.

1. Run engine a few minutes to warm oil.

2. Be sure engine is in a level position, if necessary, put a block under front roller to level engine.

4. Remove drain plug (A) and drain oil into container. If necessary, use the optional drain tube to drain oil away from unit.

6. Remove dipstick (A), wipe clean.

7. Add to full level (C). Do not overflow. (See Engine Oil in this section for correct oil.)

Oil capacity: 0.6 L (0.6 U.S. qt).

8. Wipe any spilled oil off mower.

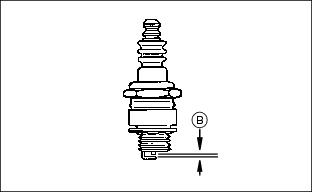

Cleaning Spark Plug And Adjusting Electrode Gap

1. Disconnect plug wire (A) and remove plug.

2. Thoroughly clean plug using high flash-point solvent and wire brush.

3. Inspect plug for cracked porcelain, pitted or damaged electrodes, or other damage.

NOTE: In Canada, replace plug with a resistor plug.

5. Check plug gap (B) with a round wire-type feeler gauge.

· Gap must be 0.7-0.8 mm

(0.028-0.031 in.).

· Change gap by moving only the outer electrode toward center electrode.

6. Install and tighten plug to 25 N·m (18 lb-ft).

Adjusting Carburetor

NOTE: The carburetor is calibrated by the engine manufacturer and should not require any adjustments.

If engine is operated at altitudes above 1829 m

(6,000 ft.), some carburetors may require a special high altitude main jet. See your John Deere dealer.

If engine is hard to start or runs rough, check the TROUBLESHOOTING section of this manual.

After performing the checks in the troubleshooting section and your engine is still not performing correctly, contact your John Deere dealer.