Introduction

Safety Labels

Controls

Operating - Machine

Operating - Cutting Units

Service Safely

Service Interval Chart

Service Lubrication

Lubricate Rotary Brush Or GTC (Greens Tender Conditioner)

Lubricate Input Drives (Continued)

Lubricate Drive Control Linkage

Lubricate Operator Presence Pawl And Cam

Service Engine

Service - Cutting Units

Service - Belts

Troubleshooting

Storing Machine

Assembly

Specifications

Warranty

John Deere Quality Statement

CopyrightŠ Deere & Company

Service Lubrication

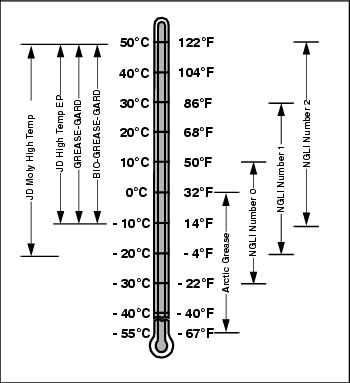

Grease

Use grease based on the expected air temperature range during the service interval.

The following greases are preferred:

ˇ John Deere Moly High Temperature EP Grease.

ˇ John Deere High Temperature EP Grease.

Other greases may be used are:

ˇ SAE Multipurpose EP Grease with 3 to 5 percent molybdenum disulfide.

ˇ Greases meeting Military Specification MIL-G-10924C may be used as arctic grease.

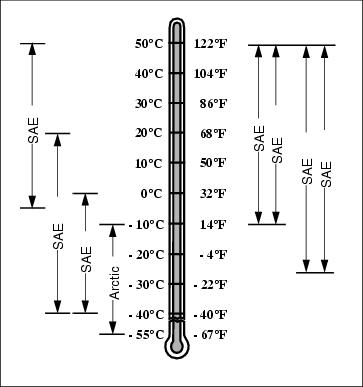

Gear Oil

Use oil viscosity based on the expected air temperature range during the period between oil changes.

John Deere GL-5 Gear Lubricant is recommended.

Other oils may be used if they meet one or more of the following:

ˇ API Service Classification GL-5.

ˇ Military Specification MIL-L-2105D.

ˇ Military Specification MIL-L-2105C.

ˇ Military Specification MIL-L-2105B.

Oils meeting Military Specification MIL-L-10324A may be used as arctic oils.

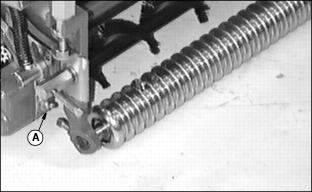

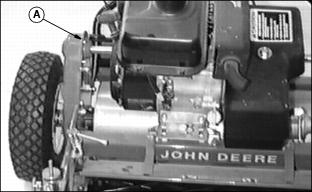

Lubricate Rotary Brush Or GTC

(Greens Tender Conditioner)

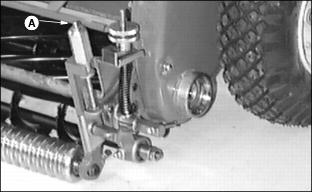

Lubricate GTC (greens tender conditioner) or rotary brush (both ends) at point (A) with John Deere EP Moly Grease or equivalent SAE multipurpose grease.

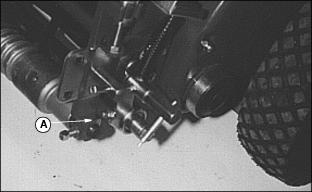

Lubricate Reel

Lubricate reel at point (A) (one each side of mower) with John Deere EP Moly Grease or equivalent SAE multipurpose grease.

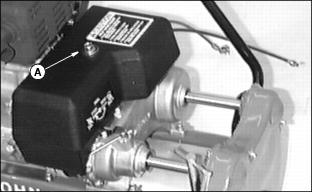

Lubricate Input Drives

Lubricate input drive to ground (right-hand side) drive chain at point (A) with John Deere EP Moly Grease or equivalent SAE multipurpose grease.

Lubricate Input Drives

(Continued)

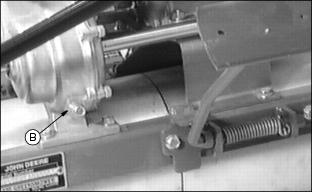

Lubricate input drive to ground (left-hand side) drive chain at point (A) with John Deere EP Moly Grease or equivalent SAE multipurpose grease.

Lubricate input drive to reel drive chain at point (B) with John Deere EP Moly Grease or equivalent SAE multipurpose grease.

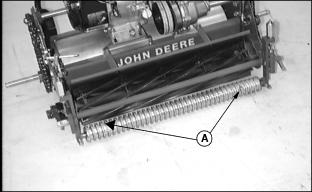

Lubricate Front Roller

Lubricate front roller at points (A) with John Deere EP Moly Grease or equivalent SAE multipurpose grease.

Lubricate Rear Roller

Lubricate rear roller at point (A) (one on each side of mower) with John Deere EP Moly Grease or equivalent SAE multipurpose grease.

NOTE: DO NOT overlubricate. Excess grease could fall from the mower during operation.

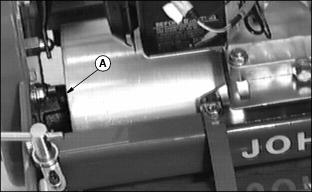

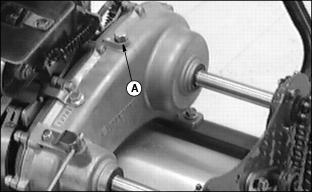

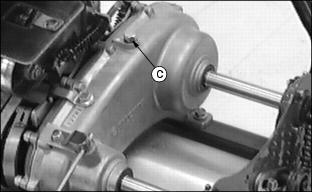

Lubricate Gear Case

1. Put block under front roller to level machine.

2. Remove dipstick (A) (15 mm).

4. Refill using SAE 85W-140 or 90 API GL-5 Gear Lubricant.

ˇ Oil capacity: 0.5 L (0.5 U.S. qt).

ˇ Oil level should be between bottom of dipstick and first mark.

NOTE: Thread dipstick into gearcase to check oil level.

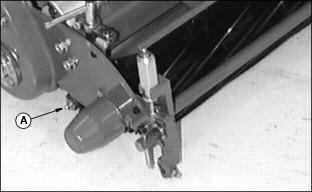

Lubricate Knife Shoe Shaft

Lubricate knife shoe shaft at point (A) (one on each side of mower) with John Deere EP Moly Grease or equivalent SAE multipurpose grease.

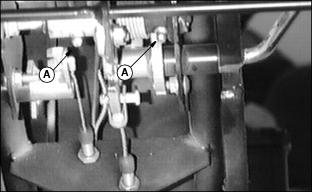

Lubricate Drive Control

Linkage

Lubricate drive control linkage at points (A) with John Deere EP Moly Grease or equivalent SAE multipurpose grease.

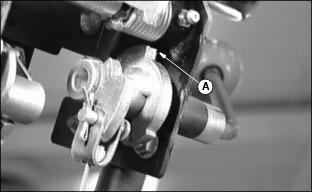

Lubricate Operator Presence

Pawl And Cam

Apply grease to operator presence pawl and cam at point (A).

Lubricate Adjusting Knobs

Lubricate adjusting knobs at point (A) (one on each side of mower) with John Deere EP Moly Grease or equivalent SAE multipurpose grease.

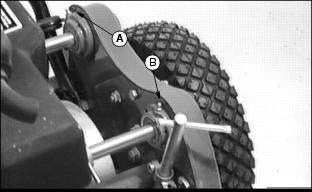

Drain And Fill Gear Case

1. Put block under front roller to level machine.

2. Loosen bolt (A) (15 mm) and remove cover.

3. Remove drain plug (B) (13 mm) and drain oil.

6. Fill gear case using SAE 85W-140

or 90 API GL-5 Gear Lubricant:

ˇ Capacity is 0.5 L (0.5 U.S. qt).

NOTE: Thread dipstick all the way in to check level.

ˇ Oil level should be between bottom of dipstick and first mark.