Introduction

Safety Labels

Controls

Operating - Machine

Operating - Cutting Units

Service Safely

Service Interval Chart

Service Lubrication

Service Engine

Service - Cutting Units

Service - Belts

Adjusting Operator Presence Bail

Troubleshooting

Storing Machine

Assembly

Specifications

Warranty

John Deere Quality Statement

CopyrightŠ Deere & Company

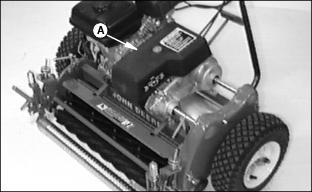

Service - Belts

Removing Drive Belts

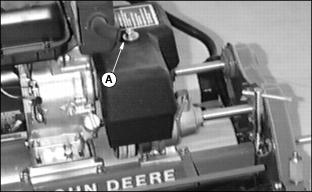

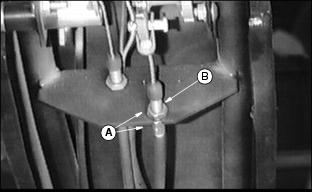

1. Remove bolt (A) (16 mm) and cover.

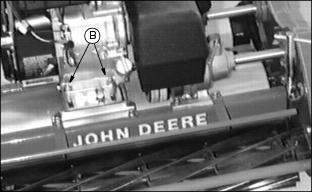

2. Remove two nuts (B) (13 mm) and bolts (on front of engine).

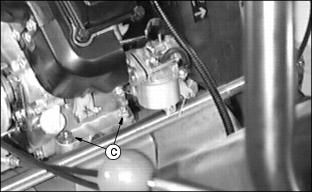

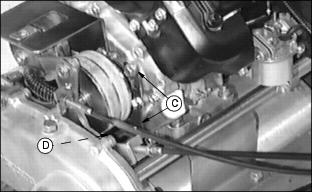

3. Remove two nuts (C) (13 mm) and bolts (on back of engine).

Installing Belts

1. Place belts on engine sheave.

2. Put engine on support with belts installed on gear case sheave.

3. Fasten with nut and bolts removed earlier. Do not tighten at this time.

4. Move engine rearward to tension belts. Engine sheave must be aligned with driven sheave.

5. Tighten four engine nuts (13 mm).

6. Check belt adjustment. (See Adjusting Drive Belts in this section.)

7. Adjust belt guide (A) using two bolts (B). There must be a clearance of approximately 1 mm (0.040-in.) between belt and guide when clutch is ENGAGED.

NOTE: Belt guide helps prevent movement when clutch is disengaged.

Adjusting Drive Belts

NOTE: With engine OFF and clutch in neutral, mower should roll freely.

When clutch is ENGAGED, main drive roller should not move. Excessive force should not be required to engage the clutch lever.

With engine running and clutch in neutral, mower should not move forward. Otherwise, additional adjustment of belt idler is required.

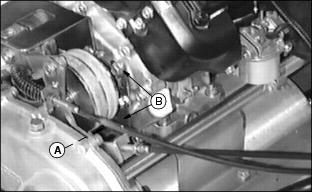

1. Loosen jam nuts (A) (one on each side of bracket).

2. Lengthen or shorten ferrule (B) to change belt idler tension.

NOTE: Set the belt idler tension just tight enough so that the main drive roller does not move when the clutch is engaged. Do not over-tighten the belt idler tension.

3. If more adjustment is needed, remove belt cover, and adjust cable at engine as done in Step 1.

ˇ If additional adjustment is needed, loosen four engine bolts

(13 mm), and slide engine to tighten or loosen belts. Engine sheave and driven sheave must align.

ˇ Tighten engine bolts. Repeat Steps 1 and 2.

Adjusting Belt Guide

1. Stop engine and wait for all moving parts to stop rotating.

3. Make sure drive belts are properly tensioned. (See Adjusting Drive Belts in this section.)

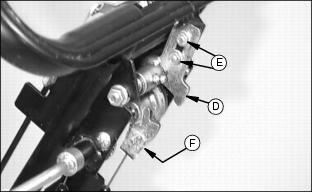

4. Move the clutch lever (B) forward to the ENGAGE position.

ˇ Adjust belt guide (D) until there is a 1 mm (0.040-in.) clearance between drive belts and guide.

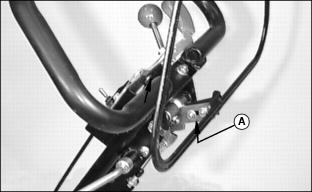

Adjusting Operator Presence Bail

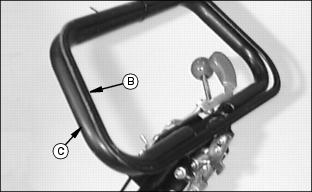

NOTE: Cover removed for clarity of photo only.

2. Position the bail (B) to the loop handlebar (C).

3. Rotate the engagement arm (D) upward as far as possible.

5. Check bail for proper operation. When bail is released, engagement arm (D) must fully engage clutch lever linkage (F).