1200A Bunker and Field Vehicle

Introduction

Safety

Controls

Operating

Replacement Parts

Service Machine Safely

Service Intervals

Service Engine

Service Transmission

Service Steering & Brakes

Service Electrical

Service Miscellaneous

Troubleshooting

Assembly

Specifications

Metric Bolt and Cap Screw Torque Values

Metric Bolt and Cap Screw Torque Values (Continued)

Metric Bolt and Cap Screw Torque Values (Continued)

Unified Inch Bolt and Cap Screw Torque Values

Unified Inch Bolt and Cap Screw Torque Values (Continued)

Unified Inch Bolt and Cap Screw Torque Values (Continued)

Warranty

John Deere Quality Statement

Specifications

Engine

Fuel System

Electrical System

Capacities

Transaxle

Travel Speeds

Steering and Brakes

Dimensions

Tires

Recommended Lubricants

(Specifications and design subject to change without notice.)

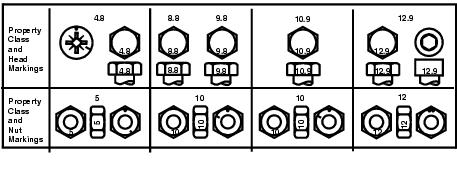

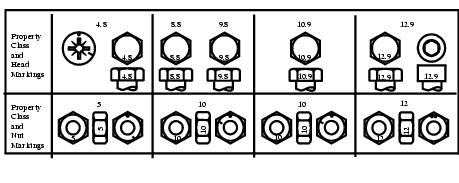

Metric Bolt and Cap Screw Torque Values

Metric Bolt and Cap Screw Torque Values (Continued)

Metric Bolt and Cap Screw Torque Values (Continued)

DO NOT use these values if a different torque value or tightening procedure is given for a specific application. Torque values listed are for general use only. Check tightness of fasteners periodically.

Shear bolts are designed to fail under predetermined loads. Always replace shear bolts with identical grade.

Fasteners should be replaced with the same or higher grade. If higher grade fasteners are used, these should only be tightened to the strength of the original. Make sure fasteners threads are clean and that you properly start thread engagement. This will prevent them from failing when tightening.

Tighten plastic insert or crimped steel-type lock nuts to approximately 50 percent of the dry torque shown in the chart, applied to the nut, not to the bolt head. Tighten toothed or serrated-type lock nuts to the full torque value.

a "Lubricated" means coated with a lubricant such as engine oil, or fasteners with phosphate and oil coatings. "Dry" means plain or zinc plated without any lubrication.

b Grade 2 applies for hex cap screws (not hex bolts) up to 152 mm (6-in) long. Grade 1 applies for hex cap screws over 152 mm (6-in) long, and for all other types of bolts and screws of any length.

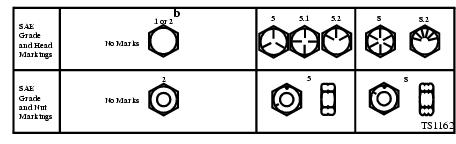

Unified Inch Bolt and Cap Screw Torque Values

Unified Inch Bolt and Cap Screw Torque Values (Continued)

Unified Inch Bolt and Cap Screw Torque Values (Continued)

DO NOT use these values if a different torque value or tightening procedure is given for a specific application. Torque values listed are for general use only. Check tightness of fasteners periodically.

Shear bolts are designed to fail under predetermined loads. Always replace shear bolts with identical grade.

Fasteners should be replaced with the same or higher grade. If higher grade fasteners are used, these should only be tightened to the strength of the original. Make sure fasteners threads are clean and that you properly start thread engagement. This will prevent them from failing when tightening. Tighten plastic insert or crimped steel-type lock nuts to approximately 50 percent of the dry torque shown in the chart, applied to the nut, not to the bolt head.

Tighten toothed or serrated-type lock nuts to the full torque value.

a "Lubricated" means coated with a lubricant such as engine oil, or fasteners with phosphate and oil coatings. "Dry" means plain or zinc plated without any lubrication.

b Grade 2 applies for hex cap screws (not hex bolts) up to 152 mm (6-in.) long. Grade 1 applies for hex cap screws over 152 mm (6-in.) long, and for all other types of bolts and screws of any length.