2653 Professional Utility Mower

Introduction

Safety Signs

Controls

Operating Machine

Operating Cutting Unit

Replacement Parts

Service Machine Safely

Service Intervals

Service Lubrication

Service Engine

Service Transmission

Transmission And Hydrostatic Oil

Changing Hydrostatic Drive Oil

Replacing Hydrostatic Oil Filter

Adjusting Transmission Neutral

Adjusting Neutral Start Switch

Service Cutting Units

Service Electrical

Service Miscellaneous

Troubleshooting

Storing Utility Mower

Assembly

CopyrightŠ Deere & Company

Service Transmission

Transmission And Hydrostatic Oil

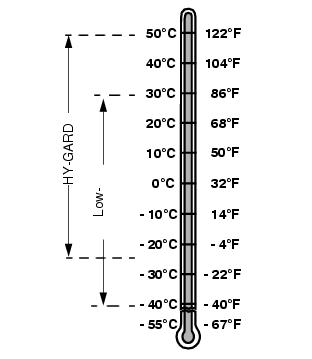

Use oil viscosity based on the expected air temperature range during the period between oil changes.

John Deere HY-GARDŽ is recommended.

Other oils may be used if they meet the following:

Use type F Automatic Transmission Fluid or John Deere All-Weather Hydrostatic Fluid.

Checking Hydraulic Oil Level

2. Lower cutting units to the ground.

4. Check oil level when oil is cold.

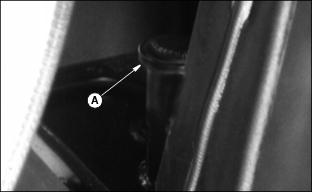

NOTE: Fill tube/dipstick (A) is behind seat.

5. Old Models: Look down the fill tube (A) to see if oil is low. Oil should be level with the bottom of fill tube screen.

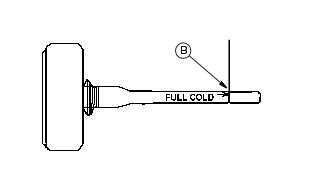

ˇ New Models: Check that oil level is at the "Full Cold" mark (B) on the dipstick.

6. If oil level is low, add John Deere HY-GARD oil or an equivalent. (See Transmission and Hydrostatic Oil in this section.)

Changing Hydrostatic Drive Oil

NOTE: Drain plug is located left rear of machine below

fuel tank.

2. Remove plug (A) and drain oil. into a drain pan with at least a 15.1 L (4 gal) capacity.

4. Fill reservoir with approximately 15.1 L (4.0 gal.) of oil.

Use John Deere HY-GARD oil or an equivalent oil meeting John Deere specifications (See Service Hydrostatic Oil in this Section.)

5. Start the engine. Cycle hydraulic control for 1 or 2 minutes.

6. Stop the engine and check oil level. Add oil as necessary.

(See Checking Hydraulic Oil Level in this section).

Replacing Hydrostatic Oil Filter

1. Stop the engine. Engage the parking brake.

2. Turn hydraulic oil filter (A) counterclockwise to remove. Use drain pan to catch dripping oil.

3. Put a film of clean oil on seal of new filter.

4. Tighten filter until it contacts mounting surface. Tighten filter one full turn after gasket contact. A filter wrench may be required.

5. Start the engine and check for leaks.

6. Stop the engine and check oil level. Add oil as necessary. (See Checking Hydraulic Oil Level in this section).

Adjusting Transmission Neutral

NOTE: Adjust transmission neutral to assure that machine DOES NOT creep when pedals are in the neutral position.

You will need a floor jack and jackstand for this procedure.

1. Park machine on a level surface.

3. Put the PTO switch in the OFF position.

4. Put the transmission in the NEUTRAL position.

5. Block left drive wheel to prevent machine from moving.

6. Raise the right drive wheel off ground with floor jack. Place a jackstand under right frame to prevent wheel from dropping.

7. Open the right-hand access cover.

8. Remove quick pin and right brake actuating rod (A).

9. Loosen bolt (B) on adjuster cam.

10. Engage the park brake. Start the engine and run at fast idle.

11. Touch hydro pedal forward and reverse. Allow pedal to return to normal.

12. Rotate eccentric (C) until right wheel does NOT spin.

13. Tighten bolt (B). Repeat Step 8.

14. Readjust eccentric if wheel begins to spin again.

15. Depress hydro pedal. If engine does not stop within 1 in. of pedal movement, readjust the neutral start switch. (See Adjusting Neutral Start Switch in this section).

16. Disengage the park brake. Reconnect brake linkage.

Adjusting Neutral Start Switch

1. Open right-hand access cover.

2. Position drive control pedal in NEUTRAL and engage the park brake.

3. Safely lift and block machine.

4. Start engine run at slow idle.

5. Move hydrostatic control pedal to the forward and reverse position. Engine should stop within first 1 in. of pedal travel.

6. If engine does not stop, switch adjustment is required.

7. Loosen two screws (B), and reposition switch (A).

8. Adjust switch (A) so it actuates as the roller touches the cam (C).