3215B TURF SYSTEM I PIN (030001-)

3225B TURF SYSTEM II PIN (020001-)

3235B TURF SYSTEM II PIN (030001-)

Introduction

Product Identification

Safety

Operating Machine

Operating Cutting Units

Replacement Parts

Service Intervals

Service Lubrication

Service Engine

Service Transmission

Service Cutting Units

Service Electrical

Service Miscellaneous

Cleaning and Repairing Plastic Surfaces

Cleaning and Repairing Plastic Surfaces

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

Service Record

CopyrightŠ Deere & Company

Service Miscellaneous

Filling Fuel Tank

Use diesel fuel Grade No. 1-D for cold air temperatures or Grade No. 2-D fuel for warm air temperatures. Diesel fuel must be cetane Number 40. A cetane number of 50 or more is preferred, especially for air temperatures below -20°C (-4°F) or elevations above 1500 m (5000 ft).

Add John Deere fuel stabilizer to fuel before using it in your machine to prevent engine damage due to stale fuel. Follow directions on stabilizer container.

1. Park machine safely. (See Park Safely in SAFETY section.)

3. Allow engine to cool several minutes.

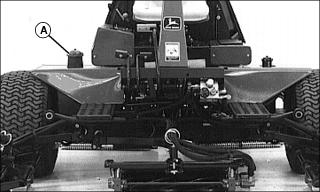

4. Remove any debris from area around red fuel tank cap (A).

6. Fill tank with fresh, stabilized fuel only to bottom of filler neck.

Greasing Rear Lift Linkage

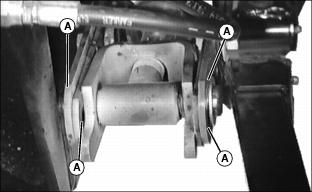

NOTE: At 200 hours or during scheduled engine oil change, a new layer of grease needs to be applied under the washers and to the short straps where they are exposed through the slot holes in the long strap.

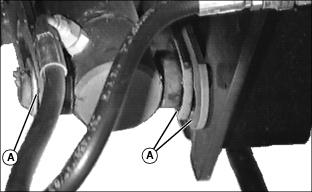

Grease lift arm (through rear of lift arms) and front cast pivots. Grease both ends of the lift linkage at locations (A).

Adjusting Park Brake

1. Park machine on level surface and turn off engine.

2. Block rear wheels and unlock park brake.

3. Support the front wheels off the ground safely, use jack stands.

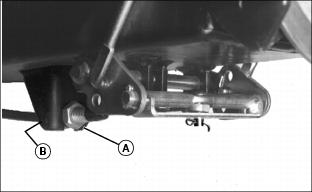

5. Tighten cable coupler nut (B) while rotating wheel until brake pads begin to contact disc. Loosen coupler until brake releases. Tighten jam nut.

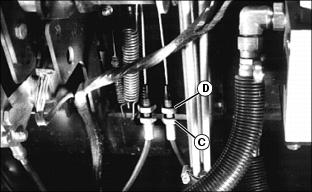

7. Loosen jam nut (C) and adjust cable coupler nut (D) as in step 5 above.

ˇ Additional adjustment is available at the pedal end of the cable.

Checking/Adjusting Toe-In

1. Park on a level surface with rear wheels in straight forward position.

2. Lower cutting units. Lock park brake and shut off engine.

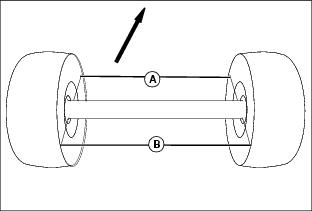

3. Measure distance (A) between tire beads at front of tire. Measure at hub height.

4. Measure distance (B) between tire beads at rear of tire. Measure at hub height.

5. Front distance (A) should be 2 to 9 mm (3/32 to 3/8 in.) less than rear distance (B). If not, adjust tie rod length.

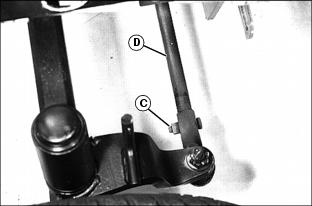

6. Loosen nut (C) on each tie rod.

7. Turn tie rod (D) until toe-in distance is 2 to 9 mm (3/32 to 3/8 in.).

9. Check steering. Ball joints must move freely.

Cleaning and Repairing Plastic Surfaces

Your John Deere dealer has the professional materials needed to properly remove surface scratches from any plastic surfaces, do not attempt to paint over marks or scratches in plastic parts.

1. Rinse hood and entire machine with clean water to remove dirt and dust that may scratch the surface.

2. Wash surface with clean water and a mild liquid automotive washing soap.

3. Dry thoroughly to avoid water spots.

4. Wax the surface with a liquid automotive wax. Use products that specifically say "contains no abrasives."

5. Buff applied wax by hand using a clean, soft cloth.

Cleaning and Repairing Plastic Surfaces

Your John Deere dealer has the professional materials needed to properly remove surface scratches from any plastic surfaces, do not attempt to paint over marks or scratches in plastic parts.

1. Rinse hood and entire machine with clean water to remove dirt and dust that may scratch the surface.

2. Wash surface with clean water and a mild liquid automotive washing soap.

3. Dry thoroughly to avoid water spots.

4. Wax the surface with a liquid automotive wax. Use products that specifically say "contains no abrasives."