3215B TURF SYSTEM I PIN (030001-)

3225B TURF SYSTEM II PIN (020001-)

3235B TURF SYSTEM II PIN (030001-)

Introduction

Product Identification

Safety

Understanding The Machine Safety Labels

Emissions Control System Certification Label

Avoid Injury From Contacting Blades

Handling Waste Product and Chemicals

Operating Machine

Operating Cutting Units

Replacement Parts

Service Intervals

Service Lubrication

Service Engine

Service Transmission

Service Cutting Units

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

Service Record

CopyrightŠ Deere & Company

Safety

Understanding The Machine Safety Labels

The machine safety labels shown in this section are placed in important areas on your machine to draw attention to potential safety hazards.

On your machine safety labels, the words DANGER, WARNING, and CAUTION are used with this safety-alert symbol. DANGER identifies the most serious hazards.

The operator's manual also explains any potential safety hazards whenever necessary in special safety messages that are identified with the word, CAUTION, and the safety-alert symbol.

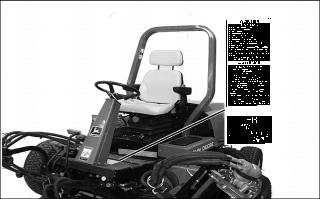

CAUTION

ˇ Maintain all safety devices.

ˇ Keep people a safe distance away.

ˇ Stay clear of power driven parts.

ˇ Do Not operate where machine could tip.

ˇ Roll-Over Protection Structure (ROPS) should be installed unless prohibited by low clearance operation.

ˇ Use seat belts unless machine is operated without ROPS.

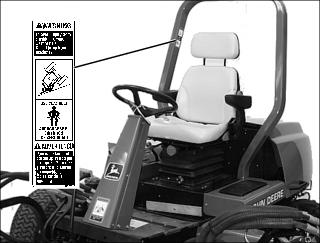

WARNING

To avoid injury, avoid quick stops and reduce speed on slopes.

WARNING

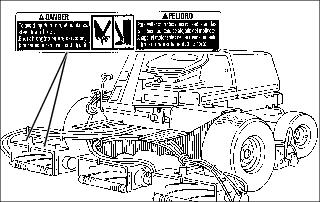

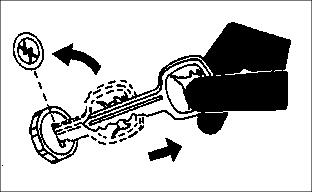

Picture Note: Two warning labels are on each cutting unit.

To avoid injury from rotating blades, stay clear of reel.

Shut off engine before servicing lubrication or removing cutting unit.

WARNING

To avoid injury from crushing, always wear seat belt. Do not jump from machine.

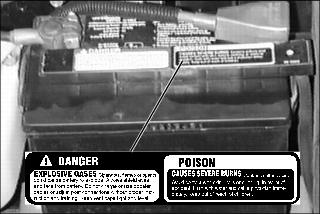

DANGER

EXPLOSIVE GASES

Cigarettes, flames or sparks could cause the battery to explode. Always shield eyes and face from battery. Do not charge or use cables or adjust poor connections without proper instructions and training. Keep vent caps tight and level

POISON CAUSES SEVERE BURNS

Contains sulfuric acid. Avoid contact with skin, eyes or clothing. In event of an accident, flush with water and call a physician immediately. Keep out of reach of children.

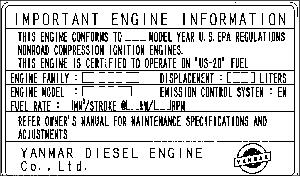

Emissions Control System Certification Label

The emissions warranty described in the warranty section applies only to those engines marketed by John Deere that have been certified by the United States Environmental Protection Agency (EPA) and/or California Air Resources Board (CARB); and used in the United States in non-road mobile (self-propelled or portable/transportable1) equipment. The presence of an emissions label like the one shown signifies that the engine has been certified with the EPA and/or CARB. The EPA and CARB warranties only apply to new engines having the certification label affixed to the engine and sold as stated above in the geographic areas governed by the regulating agencies.

NOTE: The hp/kW rating on the engine emissions certification label specifies the gross engine hp/kW, which is flywheel power without fan. In most applications this will not be the same rating as the advertised vehicle hp/kW rating.

Operator Training Required

ˇ The owner of the machine is responsible for training the users and mechanics of the machine.

ˇ The owner/user can prevent and is responsible for accidents or injuries occurring to themselves, other people, or property.

ˇ Do not allow operation or service of the machine by children or untrained adults.

ˇ Read the operator's manual and study the safety and operation sections before operating the machine.

ˇ If the operator of the machine cannot read or understand this manual, it is the machine's owner responsibility to explain this material to the operator. This publication is available in other languages.

ˇ Operate the machine in an open, unobstructed area under the direction of an experienced operator.

ˇ Learn the use of all controls.

ˇ Operator experience is required to learn the moving, stopping, turning and other operating characteristics of the machine.

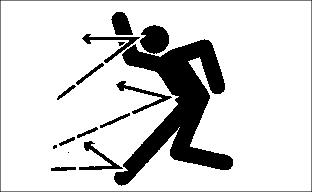

Avoid Injury From Contacting Blades

Protect Others:

ˇ Do not let untrained person operate the machine.

ˇ Be alert at all times, drive forward carefully. People can move quickly into the mowing area before you know it.

ˇ Turn machine off if another person enters the mowing area.

ˇ Shut off cutting units when you are not mowing.

ˇ Use extra care when you come to blind corners, shrubs, trees, or other objects that may block your vision.

ˇ Do not carry or let others ride on machine.

ˇ Back carefully. Shut off cutting units and look behind the machine carefully before you back up.

Blocked Or Stalled Cutting Units:

ˇ Keep all parts of the body away from the cutting edges. Residual hydraulic pressure in the system can cause cutting cylinder rotation when the blockage is released.

ˇ Do not reverse reels to unplug cutting units. Wear gloves and use tool or wood to rotate reel.

Before You Dismount To Unplug Or Adjust Cutting Units:

ˇ Stop engine and wait for reels to stop turning before making any adjustments to the cutting units.

ˇ Disengage reel drive by moving MOW/TRANSPORT lever to transport position.

Keep hands, feet, and clothing away from cutting units when engine is running.

Before Operating Mower

Remove foreign objects from machine.

Make sure all hardware is tightened.

Area to be mowed must be free from wire, stones, glass, cans, or other debris to prevent these objects from being thrown.

All guards and shields must be in place and fastened.

Brakes, steering, tires, and lights must operate correctly.

Check for hydraulic oil leaks. Hydraulic hoses and fittings must be tight. Worn or damaged hoses may burst endangering the operator or cause turf damage.

Check Ground Conditions

ˇ Clear mowing area of objects that might be thrown. Keep people and pets out of mowing area.

ˇ Study mowing area. Set up safe mowing pattern. Do not mow under conditions where traction or stability is doubtful.

ˇ First, test drive area with cutting units off but lowered. Slow down when you travel over rough ground.

Mount and Dismount Safely

Do not step on pedals when mounting or dismounting.

Do not use control levers as hand holds.

Do not use cutting unit lift arm, fender or valve as a step.

Lower cutting units, lock parking brake, stop engine, and remove key before dismounting.

Start Engine Safely

Sit on seat.

ˇ Put all operating controls in neutral.

ˇ Move Mow/Transport lever to transport position.

Operate Safely

ˇ Do not operate machine if you are under the influence of drugs or alcohol.

ˇ Check brake action before you operate. Adjust or service brakes as necessary.

ˇ Inspect machine before you operate. Be sure hardware is tight. Repair or replace damaged, badly worn, or missing parts. Be sure guards and shields are in good condition and fastened in place. Make any necessary adjustments before you operate.

ˇ Check before each use that operator presence controls are functioning correctly. Test safety systems. Do not operate unless they are functioning correctly.

ˇ Clear work area of objects that might be thrown. Keep people out of the work area. Stop machine if anyone enters the area.

ˇ If you hit an object, stop the machine and inspect it. Make repairs before you operate. Keep machine and attachments properly maintained and in good working order.

ˇ Do not leave machine unattended when it is running.

ˇ Only operate during daylight or with good artificial light.

ˇ Slow down and be careful of traffic when operating near or crossing roadways. Stop blades before crossing roads or sidewalks. Use care when approaching blind corners, shrubs, trees, or other objects that may obscure vision.

ˇ Do not wear radio or music headphones while operating the machine. Safe operation requires your full attention.

ˇ Always wear seat belt if machine has a standard ROPS or a folding ROPS in the upright position.

ˇ Stop machine if anyone enters the area.

Park Safely

1. Stop machine on a level surface, not on a slope.

3. Move Mow/Transport lever to transport.

4. Lower cutting units to the ground.

8. Wait for engine and all moving parts to stop before you leave the operator's station.

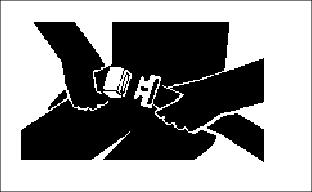

Use Seat Belt Properly

Use a seat belt when you operate with an optional roll-over protective structure (ROPS) to minimize chance of injury from an accident such as an overturn.

Do not use a seat belt if operating without a ROPS.

Check Wheel Bolts

ˇ A serious accident could occur causing serious injury if wheel bolts are not tight.

ˇ Check wheel bolt tightness often during the first 100 hours of operation. Check at 5, 50 and 100 hours.

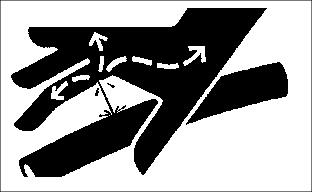

Avoid Tipping

ˇ Slopes are a major factor related to loss-of-control and tip-over accidents, which can result in severe injury or death.

ˇ Stay alert for holes and other hidden hazards in the terrain.

ˇ Do not drive where machine could slip or tip.

ˇ Keep away from drop-offs, ditches, and embankments.

ˇ Slow down before you make a sharp turn or operate on a slope.

ˇ Be careful when you change direction on a slope.

ˇ Do not stop when going up hill or down hill. If machine stops going up hill, raise cutting units and back down slowly.

Keep Riders Off

ˇ Only allow the operator on the machine. Keep riders off.

ˇ Riders on the machine or attachment may be struck by foreign objects or thrown off the machine causing serious injury.

ˇ Riders obstruct the operator's view resulting in the machine being operated in an unsafe manner.

Wear Appropriate Clothing

ˇ Wear close fitting clothing and safety equipment appropriate for the job.

ˇ Always wear safety goggles or safety glasses with side shields when operating the mower.

ˇ Wear a suitable protective device such as earplugs. Loud noise can cause impairment or loss of hearing.

ˇ Do not wear radio or music headphones. Safe service and operation requires your full attention.

Avoid Neutral Creep

The machine may creep forward or backward while in neutral with engine running and parking brake unlocked.

After engine has started, release parking brake and with the directional speed control pedals in their neutral position the machine should not move.

If movement is evident, Neutral Return mechanism is adjusted incorrectly. Shut off engine and adjust until machine does not move when directional speed control pedals are in neutral position.

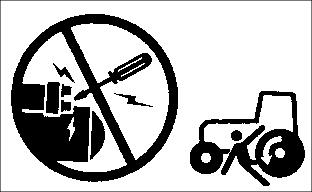

Prevent Machine Runaway

Avoid possible injury or death from machinery runaway.

Do not start engine by shorting across starter terminals. Machine may start in gear if normal circuitry is bypassed.

NEVER start engine while standing on ground. Start engine only from operator's seat, with transmission in neutral.

Avoid High Pressure Fluids

ˇ Hydraulic hoses and lines can fail due to physical damage, kinks, age, and exposure. Check hoses and lines regularly. Replace damaged hoses and lines.

ˇ Hydraulic fluid connections can loosen due to physical damage and vibration. Check connections regularly. Tighten loose connections.

ˇ Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure.

ˇ Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids.

ˇ If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A. Information may be obtained in the United States and Canada only by calling 1-800-822-8262.

Practice Safe Maintenance

ˇ Understand service procedure before doing work. Keep area clean and dry.

ˇ Never lubricate, service, or adjust machine while it is moving. Keep safety devices in place and in working condition. Keep hardware tight.

ˇ To prevent them from getting caught, keep hands, feet, clothing, jewelry, and long hair away from any moving parts.

ˇ Before servicing machine, lower attachments to the ground. Disengage all power and stop the engine. Move hydraulic lift levers back and forth to relieve pressure. Lock park brake and remove the key. Let machine cool.

ˇ Securely support any machine elements that must be raised for service work.

ˇ Never run engine unless park brake is locked.

ˇ Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or debris.

ˇ Disconnect battery ground cable (-) before making adjustments on electrical systems or welding on machine.

ˇ Unauthorized modifications to the machine may impair its function and safety.

Handling Waste Product and Chemicals

ˇ Waste products, such as, used oil, fuel, coolant, brake fluid, and batteries, can harm the environment and people.

ˇ Do not use beverage containers for waste fluids - someone may drink from them.

ˇ See your local Recycling Center or John Deere dealer to learn how to recycle or get rid of waste products.

ˇ A Material Safety Data Sheet (MSDS) provides specific details on chemical products: physical and health hazards, safety procedures, and emergency response techniques. The seller of the chemical products used with your machine is responsible for providing the MSDS for that product.

Tire Safety

Explosive separation of a tire and rim parts can cause serious injury or death:

ˇ Do not attempt to mount a tire without the proper equipment and experience to perform the job.

ˇ Always maintain the correct tire pressure. Do not inflate the tires above the recommended pressure. Never weld or heat a wheel and tire assembly. The heat can cause an increase in air pressure resulting in a tire explosion. Welding can structurally weaken or deform the wheel.

ˇ When inflating tires, use a clip-on chuck and extension hose long enough to allow you to stand to one side and not in front of or over the tire assembly.

ˇ Check tires for low pressure, cuts, bubbles, damaged rims or missing lug bolts and nuts.

Handling Fuel Safely

Fuel and fuel vapors are highly flammable and explosive:

ˇ Do not refuel machine while you smoke, when machine is near an open flame or sparks, or when engine is running. Stop engine and allow to cool before filling.

ˇ Never remove the fuel cap or add fuel with the engine running.

ˇ Never fill fuel tank or drain fuel from a machine in an enclosed area. Fill fuel tank outdoors.

ˇ Prevent fires. Clean up spilled fuel immediately.

ˇ Do not store machine with fuel in tank in a building where fumes may reach an open flame or spark.

ˇ Prevent fire and explosion caused by static electric discharge. Use only non-metal, portable fuel containers approved by the Underwriter's Laboratory (U.L.) or the American Society for Testing & Materials (ASTM). If using a funnel, make sure it is plastic and has no screen or filter.

ˇ Static electric discharge can ignite gasoline vapors in an ungrounded fuel container. Remove the fuel container from the bed of a vehicle or the trunk of a car and place on the ground away from the vehicle before filling. Keep nozzle in contact with container opening while filling.

ˇ When practical, remove equipment from trailers or truck beds and refuel them on the ground. If this is not possible, use a portable, plastic fuel container to refuel equipment on a truck bed or trailer.

Transport Machine Safely

Slow-moving machines when driven on public roads are hard to see, especially at night. Equip mower with light kit and other appropriate safety features to avoid personal injury or death resulting from a collision with another vehicle.

When transporting on public roads use a Slow Moving Vehicle (SMV) emblem day or night. An SMV kit is available from your John Deere dealer.