3215B TURF SYSTEM I PIN (030001-)

3225B TURF SYSTEM II PIN (020001-)

3235B TURF SYSTEM II PIN (030001-)

Introduction

Product Identification

Safety

Operating Machine

Operating Cutting Units

Replacement Parts

Service Intervals

Service Lubrication

Grease Locations: Lubricate Daily

Grease Locations - Lubricate Weekly

Service Engine

Service Transmission

Service Cutting Units

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

Service Record

CopyrightŠ Deere & Company

Service Lubrication

Grease

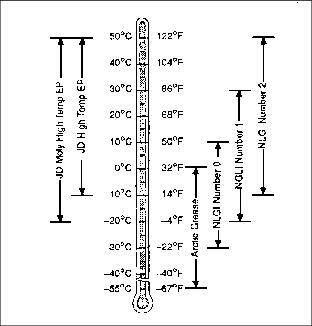

Use grease based on the expected air temperature range during the service interval.

The following greases are preferred for cutting units:

ˇ Polyurea - NLGI Grade 0 grease.

ˇ Calcium Complex Grease - NLGI Grade 0 grease.

The following greases are preferred for traction units:

ˇ John Deere Non-Clay High Temperature #2 grease.

Greases meeting Military Specification MIL-G-10924F may be used as arctic grease.

Grease Locations: Lubricate Daily

IMPORTANT: Avoid damage! Lubricate immediately after washing the machine to remove water before bearings cool and "suck in" water and contaminates. |

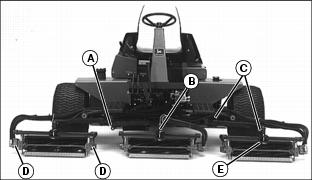

A - Lift Cylinder End - 6 places

C - Lift Arms and Pivots - 3 places

D - Rear Rollers (both ends) - 10 places

E - RFS Spring (22 ESP) - 5 places

A - Rear Roller Bearings (both ends) - 10 places

B - Front Rollers (both ends) - 10 places

Grease Locations - Lubricate Weekly

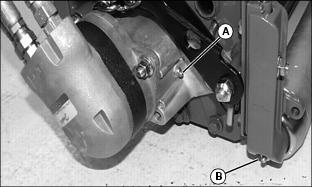

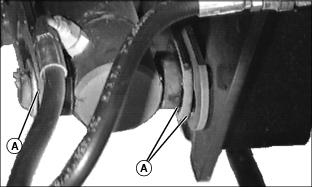

A - Follower Bearing (3215B/3225B)

A - Eccentric on Neutral Start Linkage (3215B/3225B)

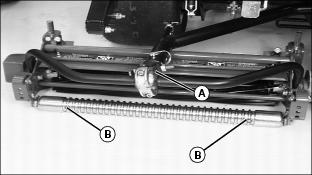

Greasing Rear Lift Linkage

NOTE: At 200 hours or during scheduled engine oil change, a new layer of grease needs to be applied under the washers and to the short straps where they are exposed through the slot holes in the long strap.

Grease lift arm (through rear of lift arms) and front cast pivots. Grease both ends of the lift linkage at locations (A).