Introduction

Safety Signs

Controls

Operating

Replacement Parts

Service Machine Safely

Service Intervals

Service Lubrication

Service Engine

Service Transmission

Service Cutting Units

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

CopyrightŠ Deere & Company

Service Miscellaneous

Checking Tire Pressure

2. Check tire pressure with an accurate gauge.

4. Keep tire pressure at 62 kPa (9psi) (0.6 bar).

Refueling Machine

Fuel Tank

Fuel tank cap is vented. Use only a vented cap.

Fuel Tank Capacity: 75.5 L (20 gal).

Fill fuel tank at end of each day's operation.

If engine runs out of fuel, fill fuel tank and bleed fuel system. See Bleeding Fuel System in Service-Engine section.

Fuel Specifications

Use Grade No. 2-D fuel at temperatures above 40

Use Grade No. 1-D fuel at temperatures below 40

Use Grade No. 1-D fuel for all air temperatures at altitudes above 1500 mm (5000 ft).

For maximum filter life, sediment and water should not be more than 0.10 percent.

The cetane number should be 40 minimum. If operating where air temperatures are normally low or where altitudes are high, fuel with a higher cetane number may be needed.

Cloud Point weather operation should be 6°C (10°F) below lowest normal air temperature.

Filling The Fuel Tank

Fill fuel tank at the end of each day's operation to prevent condensation and freezing during cold weather.

Fuel Tank Capacity: 75.5 L (20 gal).

1. STOP engine. If engine is hot let it cool several minutes before you add fuel.

2. Remove any trash from area around fuel tank.

4. Fill fuel tank at end of each day's operation or when fuel gauge shows 1/4 or less fuel in tank. Fill fuel tank only to bottom of filler neck.

Fuel Storage

NOTE: Diesel fuels stored for a long time may form gum and plug filters.

Keep fuel in a clean container in a protected area.

Water and sediment must be removed before fuel gets to the engine.

Do not use de-icers or depend on fuel filters to remove water from fuel.

Install a water separator at the storage tank outlet. See your John Deere distributor for this part.

Store fuel drum on side with plug up.

Fuel Containers

DO NOT USE galvanized or brass-coated containers to store diesel fuel. Brass is an alloy of copper and zinc.

ˇ Specially coated steel containers made for diesel fuel.

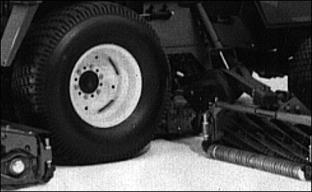

Tightening Wheel Bolts

After first 10 hours of operation and every 50 hours thereafter:

Tighten steered wheel nuts (small tires) to 81 to 95 Nmm to (70 lb-ft).

Tighten drive wheel bolts (large tires) to 136 Nmm (100 lb-ft).

Correct Hydraulic Routings

IMPORTANT: Avoid damage! Hydraulic leaks and hose failure may damage machine and turf area. Install hoses correctly. |

Hoses must be free of twists and kinks before and after tightening fittings. Use a second wrench to hold hose when tightening fittings.

Plastic tie straps should be used to avoid damage to hoses.

Using Service Records

1. Keep a record of the number of hours machine is used.

2. Check records regularly and service at recommended intervals.

3. DO ALL services in an interval section. Record number of hours and date serviced.

Distributor Services

The following services require special tools and procedures. See your John Deere distributor.