Introduction

Safety Signs

Controls

Operating

Rotating Blades Are Dangerous - Protect Others And Prevent Accidents

Stay Clear Of Rotating Drivelines

Driving: Using And Adjusting Parking Brake Lock

Using Liquid Ballast (Continued).

Adjusting Weight Transfer System (With Pressure Gauge)

Adjusting Weight Transfer System (Without Pressure Gauge)

Using Two-Speed Axle Shift Lever

Using Power Assist Rear Wheel Drive

Avoid Damage To Plastic And Painted Surfaces

Replacement Parts

Service Machine Safely

Service Intervals

Service Lubrication

Service Engine

Service Transmission

Service Cutting Units

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

CopyrightŠ Deere & Company

Operating

Operate Safely

ˇ Check brake action before you operate. Adjust or service brakes as necessary.

ˇ Clear work area of objects that might be thrown. Keep people and pets out of the work area. Stop machine if anyone enters the area.

ˇ If you hit an object, stop the machine and inspect it. Make repairs before you operate. Keep machine and attachments properly maintained and in good working order. Keep all shields and guards in place.

ˇ DO NOT leave machine unattended when it is running.

ˇ Only operate during daylight or with good artificial light.

ˇ Be careful of traffic when operating near or crossing roadways.

ˇ Drive slowly over rough ground.

ˇ Do not wear radio or music headphones while operating the machine. Safe operation requires your full attention.

ˇ First, test drive area with cutting units OFF but lowered. Slow down when you travel over rough ground.

ˇ Never change engine governor setting or over-speed the engine.

Mount And Dismount Safely

ˇ DO NOT step on pedals when mounting or dismounting.

ˇ Keep step area and platform clean.

ˇ DO NOT use cutting unit lift arm as a step.

ˇ Lock parking brake, stop engine, and remove key before dismounting.

Park Safely

ˇ Stop machine on a level surface, not on a slope.

ˇ Lower cutting units to the ground.

ˇ Before you leave the operator's seat, wait for engine and all moving parts to STOP.

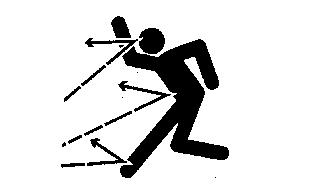

Keep Riders Off

ˇ Only allow the operator on the machine. Keep riders off.

ˇ Riders on the machine or attachment may be struck by foreign objects or thrown off the machine causing serious injury.

ˇ Riders obstruct the operator's view resulting in the machine being operated in an unsafe manner.

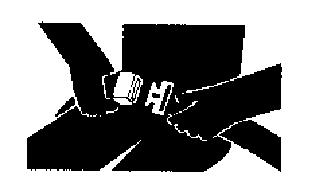

Use Seat Belt Properly

Use a seat belt when you operate with a roll-over protective structure (ROPS) or cab to minimize chance of injury from an accident such as an overturn.

DO NOT use a seat belt if operating without a ROPS or cab.

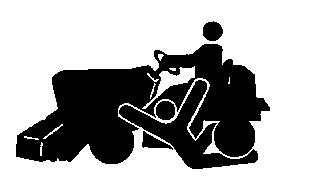

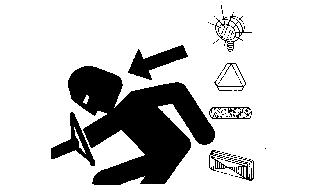

Rotating Blades Are Dangerous - Protect Others And Prevent Accidents

ˇ Turn machine off if another person enters the mowing area.

ˇ Use extra care when you come to blind corners, shrubs, trees, or other objects that may block your vision.

ˇ DO NOT let untrained person operate the machine.

ˇ DO NOT carry or let others ride on machine.

HELP PREVENT SERIOUS OR FATAL ACCIDENTS:

ˇ Be alert at all times, drive forward carefully. People can move quickly into the mowing area before you know it.

ˇ DO NOT operate machine if you are under the influence of drugs or alcohol.

ˇ Back carefully. Shut off cutting units and look behind the machine carefully before you back up.

ˇ Shut off cutting units when you are not mowing.

ˇ Stop engine and wait for reels to stop turning before making any adjustments to the cutting units.

ˇ Keep hands and feet away from cutting units while machine is running.

Avoid Tipping

ˇ DO NOT drive where machine could slip or tip.

ˇ Stay alert for holes and other hidden hazards in the terrain.

ˇ Slow down before you make a sharp turn or operate on a slope.

ˇ Drive up and down a hill - not across. Be careful when you change direction on a slope.

ˇ DO NOT try to stabilize the machine by putting your foot on the ground.

ˇ Study mowing area. Set up safe mowing pattern. Do not mow under conditions where traction or stability is doubtful.

ˇ DO NOT stop when going up hill or down hill. If machine stops going up hill, STOP CUTTING UNITS and back down slowly.

Operator Training Required

ˇ Study operation section of this manual before operating the machine.

ˇ Operate machine in an open, unobstructed area under the direction of an experienced operator.

ˇ Learn the use of all controls.

ˇ Operator experience is required to learn the moving, stopping, turning and other operating characteristics of the machine.

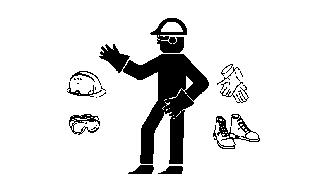

Wear Appropriate Clothing

ˇ Wear close fitting clothing and safety equipment appropriate for the job.

ˇ Loud noise can cause impairment or loss of hearing, wear a suitable protective device such as earplugs.

ˇ Do not wear radio or music headphones while operating the machine. Safe operation requires your full attention.

Check Wheel Bolts

ˇ A serious accident could occur causing serious injury if wheel bolts are not tight.

ˇ Check wheel bolt tightness often during the first 100 hours of operation.

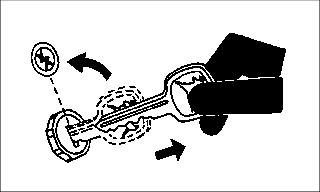

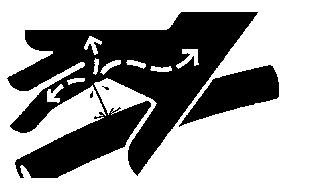

Stay Clear Of Rotating Drivelines

Entanglement in rotating driveline can cause serious injury or death:

ˇ Wear close fitting clothing.

ˇ STOP the engine and be sure PTO driveline is stopped before getting near it.

Transport Safely

ˇ Use safety lights and devices. Slow moving machines when driven on public roads are hard to see, especially at night. Avoid personal injury or death resulting from a collision with a vehicle.

ˇ Flashing warning lights are recommended whenever driving on public roads to increase visibility. Extra flashing warning lights may need to be installed.

ˇ DO NOT tow behind any vehicle.

Prevent Machine Runaway

ˇ DO NOT start engine by shorting across starter terminals. Machine will start in gear if normal circuitry is bypassed.

ˇ NEVER start engine while standing on the ground. Start engine only from operator's seat with transmission in neutral.

Avoid Neutral Creep

ˇ The machine may creep forward or backward while in neutral with engine running.

ˇ After engine has started, release parking brake and with directional speed control speed pedals centered, machine should not move.

ˇ If movement is evident, neutral return mechanism is adjusted incorrectly. (See Adjusting Transmission Neutral in Service- Transmission section).

Avoid High Pressure Fluids

ˇ Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure.

ˇ Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids.

ˇ If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A.

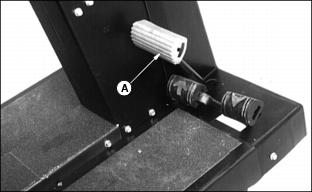

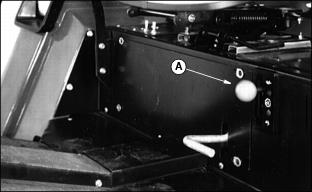

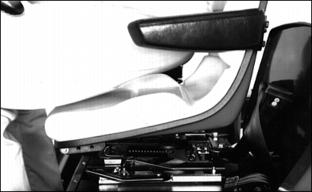

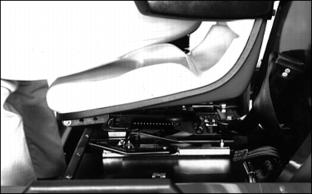

Adjustments: Seat

Push handle (A) away from seat and slide seat forward or backward. Release lever to lock position.

Adjustments: Toe-In

1. Park machine on level surface.

2. Turn steering wheel so front wheels are in the straight-ahead position.

3. Lower attachment to ground. Lock parking brake. Stop engine. Remove key.

4. Measure distance between tire beads at front and rear of tire, hub height.

5. Front distance should be 3 mm (1/8 in.) less than rear distance. If not, adjust tie rod length.

6. Loosen tie rod nut on both tie rod ends.

7. Turn tie rod until toe-in is to specification.

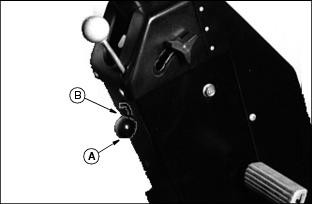

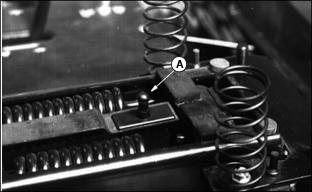

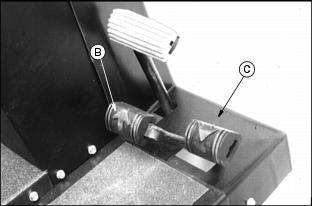

Driving: Using And Adjusting Parking Brake Lock

Depress parking brake pedal and lower knob (A) to engage lock until it latches.

Release lock by depressing brake pedal and moving knob to position (B).

1. Remove yoke from park brake pedal.

When knob (A) is in lowest part of slot on steering column, the brake pawl should engage notch on brake pedal when pedal is depressed.

Starting The Engine

1. With machine and PTO in neutral, depress brake pedal (A) and set throttle (B) to 1/3 throttle.

2. Turn key to ON, preheater light must go out.

Stopping The Engine

NOTE: If ignition system fails to stop engine when key is turned OFF, diesel engine may be manually stopped by pushing injection pump lever rearward away from shut-off solenoid (B).

Emergency Stopping

Push hard on service-parking brake pedal. Disengage PTO.

Checking Interlock Switches

1. Sit on seat and start engine.

NOTE: Interlock switch (A) is depressed when sitting

on seat.

2. With engine running, engage PTO lever and lower reels. Reels should turn.

3. Raise up off seat, engine should stop. Check in backlapping position also. See Backlapping Cutting Units in Service-Cutting Units section.

4. Sit on seat, lock parking brake, and start engine.

5. Put two-speed axle control lever in neutral, depress forward speed control pedal (B) slowly and lift up off seat. Engine should stop.

6. Stop engine. Depress forward speed control pedal (B). Engine should not start when key is turned.

7. Stop engine. Test in backlapping position also. See Backlapping Cutting Units in Service-Cutting Units section.

Operating On Slopes

When operating on slopes, do the following:

ˇ Install front wheel weights.

ˇ Have your John Deere distributor add fluid to all tires.

ˇ The angle of slope the machine can be safely operated on will vary with the type of terrain and speed.

ˇ DO NOT park mower on a slope.

ˇ If engine stops when going uphill, shut off PTO, lock parking brake, start engine, release parking brake, and back down slowly.

Adding Ballast

ˇ Ballast may be added by filling front tires with fluid or adding wheel weights.

ˇ Adding ballast can improve traction in adverse conditions and improve stability on side slopes.

ˇ Excessive ballast will increase compaction and could cause damage to turf.

ˇ Traction can be increased further by using the weight transfer system.

Using Liquid Ballast

A solution of water and calcium chloride provides safe economical ballast. Used properly, it will not damage tires, tubes or rims.

Use calcium chloride to prevent water from freezing. A mixture of 0.4 kg calcium chloride per liter (4 lb per gallon) will not freeze solid down to -45°C (50°F).

NOTE: Use of alcohol as liquid ballast is not recommended. Calcium chloride solution is heavier and more economical.

Using Liquid Ballast (Continued).

IMPORTANT: Avoid damage! Never fill any tire to more than 90% full. More solution would leave too little air space to absorb shocks. Damage to tire could occur. |

Fill tubeless tires at least to valve level (minimum 75% full). Less solution would expose part of rim, possibly causing corrosion. Tube-type tires may be filled to any level below 90%. For 75% fill in 33 x 12.50 x 15 tires, use 107 kg (235 lb) liquid.

Calcium chloride kills grass, move machine off turf if leaks occur.

Wheel Weights

Attach optional 27 kg (60 lb) weight to front wheels.

A total of three weights per wheel may be added.

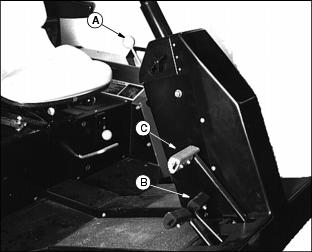

Using Cruise Control

NOTE: Cruise control operates only in forward travel.

ˇ Pulling cruise control knob (A) up.

ˇ Pushing forward speed control pedal (B) at least 1/3 of the way down.

ˇ Removing foot from forward speed control pedal.

ˇ Removing hand from cruise control knob.

ˇ Tapping forward speed control pedal (B).

ˇ Pushing down on cruise control knob (A).

ˇ Depressing service-parking brake pedal (C).

Using Differential Lock

NOTE: Differential will stay locked as long as lever is held down.

To avoid turf damage engage the differential for better traction on slopes and in slippery areas BEFORE wheels start to slip.

2. Push lever (A) down to engage differential. DO NOT engage when wheels are slipping.

3. Release lever to disengage differential.

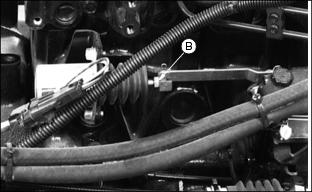

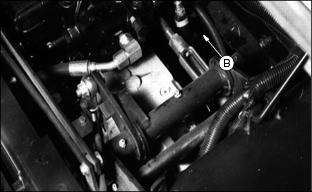

Adjusting Weight Transfer System (With Pressure Gauge)

A diagnostic coupler at the priority valve (B) can be used to measure the amount of weight transfer.

1. Connect a 0 to 3500 kPa (0 to 35 bar) (0 to 500 psi) gauge to the coupler to measure system pressure.

2. Run engine at full throttle to warm oil. Turn thumbscrew counterclockwise completely to minimize weight transfer. Note system pressure.

3. Turn thumbscrew clockwise to increase system pressure. System pressure can be adjusted to any setting from 700 to 3500 kPa (7 to 35 bar) (100 to 500 psi). Scale reading decreases as pressure increases.

4. Adjust weight transfer as necessary to achieve desired traction or reduce weight of cutting unit on the turf.

5. Additional weight can be added to drive wheels by adding ballast to the drive wheels in the form of fluid or wheel weights. Excessive weight on drive wheels can cause compaction and damage turf. It may be desirable to transfer weight from cutting units to drive wheels in soft turf or newly seeded turf areas.

6. Adjusting weight transfer may require an adjustment in cutting unit drop rate. See Adjusting Rate-Of-Drop in this section.

7. Adjust drop rate so cutting units will follow ground contour as desired. Turn drop rate screws (C) counterclockwise to increase drop rate.

8. If the cutting units will not follow ground contour as desired, increase drop rate and/or decrease weight transfer pressure.

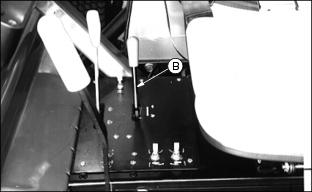

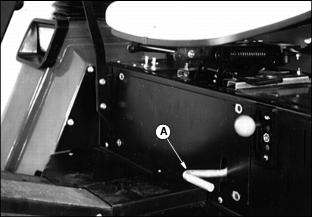

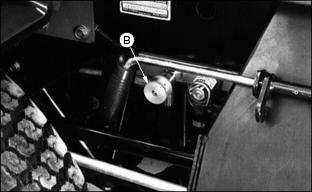

Adjusting Weight Transfer System (Without Pressure Gauge)

1. Run engine at full throttle to warm oil.

2. Turn on weight transfer switch (A).

3. Turn thumbscrew counterclockwise completely to minimize weight transfer.

4. Operate on turf and turn thumbscrew (B) clockwise to adjust weight transfer as necessary to achieve desired traction or reduce weight of cutting unit on turf.

5. Additional weight can be added to drive wheels by adding ballast to drive wheels in form of fluid or wheel weights.

6. Excessive weight on drive wheels can cause compaction and damage turf. It may be desirable to transfer weight from cutting units to drive wheels in soft turf or newly seeded turf areas.

7. Adjusting weight transfer may require an adjustment in cutting unit drop rate. See Adjusting Rate-of Drop in this section.

8. Adjust drop rate so cutting units will follow ground contour as desired. Turn drop rate screws counterclockwise to increase drop rate.

9. If the cutting units will not follow ground contour as desired, increase drop rate and/or decrease weight transfer pressure.

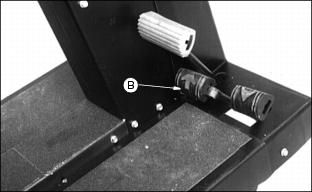

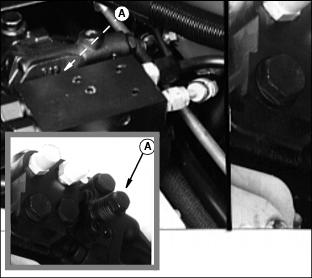

Adjusting Rate-Of-Drop

IMPORTANT: Avoid damage! Allowing cutting units to drop too fast can damage turf and/or cutting units. |

NOTE: Adjust rate-of-drop so cutting units raise and drop at the speed adequate for the type of turf to be mowed.

1. Run engine at high idle and warm the oil.

2. Turn screw (A) clockwise to reduce rate-of-drop on three center cutting units.

3. Turn knobs (B) clockwise to reduce rate-of-drop on wing

units.

Using Two-Speed Axle Shift Lever

NOTE: Lever (A) must be in FAST or SLOW range before mower will move.

Disengage PTO when transporting.

ˇ Move lever to SLOW range 0 to 11.6 km/h (0 to 7.2 mph) for mowing.

ˇ Move lever to FAST range 0 to 18.8 km/h (0 to 11.7 mph) for mowing or transporting.

Using Power Assist Rear Wheel Drive

NOTE: Listen for a soft clicking sound at the rear axle valve solenoid to insure proper wiring function.

ˇ To turn Power Assist ON push toggle switch (A) up.

ˇ To turn Power Assist OFF pull toggle switch (A) down.

Power Assist can be used in High or Low range and is recommended to turn on and leave on during normal mowing operations.

DAILY OPERATING CHECKLIST

ˇ Remove grass and debris from machine.

TESTING SAFETY SYSTEMS

Use the following checkout procedure to check for normal operation of turf mower.

If there is a malfunction during one of these procedures, DO NOT operate machine. (See your John Deere distributor for service.)

Perform these tests in a clear open area. Keep bystanders away.

Test 1

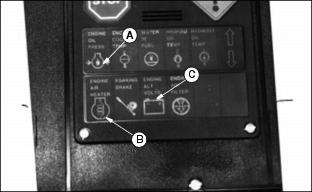

Check operation of indicator lights:

ˇ LOOK: Indicator lights (A) and (C) must light.

ˇ LOOK: Indicator light (B) will come on and go out within approximately 8 seconds. If the engine has been run and then cooled, the time may be less. If the engine has been run and is hot, the light will not come on.

ˇ If one indicator does not light, see Replacing Indicator Light Bulb in SERVICE-ELECTRICAL section.

ˇ If new indicator bulb does not light or no indicators work, see your John Deere distributor.

Test 2

1. Unlock park brake and release brake pedal.

2. Turn key to START position.

Test 3

1. Depress brake pedal, or lock park brake.

2. Put PTO switch lever in ON position.

3. Turn key to START position.

Test 4

ˇ Start engine. Run engine at MAXIMUM engine speed.

ˇ Unlock park brake and release brake pedal.

ˇ Put PTO switch lever in ON position.

ˇ Raise up off seat. DO NOT get off tractor.

ˇ Engine should begin to die. PTO should immediately SHUT OFF and mower blades should STOP.

ˇ Raise up off seat. DO NOT get off tractor.

ˇ Raise up off seat. DO NOT get off tractor.

ˇ Engine should continue to run.

Test 5

Check Interlock Switch Functions:

1. Sit on operator's seat to activate the seat switch (A).

2. Turn key switch on. Buzzer must sound.

4. Run engine at 1/3 throttle.

5. Push PTO lever forward to engage PTO.

6. Raise off seat a few inches. After 1/2 second, engine must stop.

7. Slowly push forward speed control pedal (B) down.

8. Raise off seat a few inches. After 1/2 second engine must stop.

9. Slowly, push rearward speed control pedal (C) down.

10. Raise off seat a few inches. After 1/2 second engine must stop.

11. If engine does not stop during one of the above tests, do not operate mower. See your John Deere distributor.

Avoid Damage To Plastic And Painted Surfaces

ˇ Insect repellent spray may damage plastic and painted surfaces. Do not spray insect repellent near machine.

ˇ Be careful not to spill fuel on machine. Fuel may damage surface. Wipe up spilled fuel immediately.

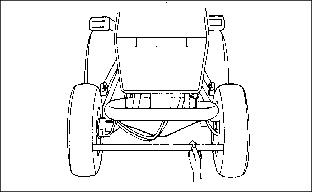

Transporting Machine

Use a heavy-duty trailer to transport your machine.

Tire inflation should be to 20-30 psi shipping pressure to ensure machine will not move after being fastened to trailer.

Drive machine forward onto a trailer. Lower any attachments to trailer deck.

Fasten machine to trailer with heavy-duty straps, chains, or cables. Both front and rear straps must be directed down and outward from machine.