Introduction

Safety Signs

Controls

Operating

Replacement Parts

Service Machine Safely

Stay Clear Of Rotating Drivelines

Handling Waste Product And Chemicals

Remove Paint Before Welding Or Heating

Avoid Heating Near Pressurized Fluid Lines

Handle Fuel Safely Avoid Fires

Roll-Over Protective Structure (ROPS)

Avoid Injury From Moving Parts

Service Intervals

Service Lubrication

Service Engine

Service Transmission

Service Cutting Units

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

CopyrightŠ Deere & Company

Service Machine Safely

Practice Safe Maintenance

ˇ Understand service procedure before doing work. Keep area clean and dry.

ˇ Never lubricate, service, or adjust machine while it is moving. Keep safety devices in place and in working condition. Keep hardware tight.

ˇ To prevent them from getting caught, keep hands, feet, clothing, jewelry, and long hair away from any moving parts.

ˇ Before servicing machine, lower attachments to the ground. Disengage all power and stop the engine. Move hydraulic lift levers back and forth to relieve pressure. Lock park brake and remove the key. Let tractor cool.

ˇ Securely support any machine elements that must be raised for service work.

ˇ Never run engine unless park brake is locked.

ˇ Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or debris.

ˇ Disconnect battery ground cable (-) before making adjustments on electrical systems or welding on tractor.

ˇ Unauthorized modifications to the tractor may impair its function and safety.

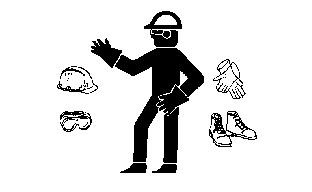

Wear Appropriate Clothing

ˇ Wear close fitting clothing and safety equipment appropriate for the job.

ˇ Loud noise can cause impairment or loss of hearing, wear a suitable protective device such as earplugs.

ˇ Do not wear radio or music headphones while servicing the machine. Safe service requires your full attention.

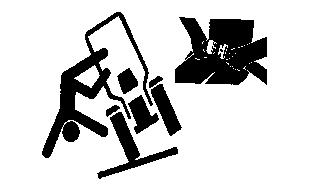

Stay Clear Of Rotating Drivelines

Entanglement in rotating driveline can cause

serious injury or death:

ˇ STOP the engine and be sure PTO driveline is stopped before getting near it.

Handling Waste Product And Chemicals

ˇ Waste products, such as, used oil, fuel, coolant, brake fluid, and batteries, can harm the environment and people.

ˇ DO NOT use beverage containers for waste fluids - someone may drink from them.

ˇ See your local Recycling Center or John Deere dealer to learn how to recycle or get rid of waste products.

ˇ A Material Safety Data Sheet (MSDS) provides specific details on chemical products: physical and health hazards, safety procedures, and emergency response techniques. See your John Deere dealer for the MSDS on chemical products used with your machine.

Avoid High Pressure Fluids

ˇ Hydraulic hoses can fail due to physical damage, kinks, age, and exposure. Check hoses regularly. Replace damaged hoses.

ˇ Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure.

ˇ Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids.

ˇ If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A.

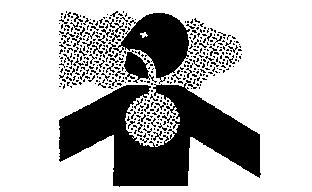

Remove Paint Before Welding Or Heating

ˇ Avoid potentially toxic fumes and dust.

ˇ Hazardous fumes can be generated when paint is heated by welding, soldering, or using a torch.

ˇ Do all work outside or in a well ventilated area. Dispose of paint and solvent properly.

ˇ Remove paint before welding or heating.

ˇ IF you sand or grind paint, avoid breathing the dust. Wear an approved respirator.

ˇ IF you use solvent or paint stripper, remove stripper with soap and water before welding. Remove solvent or paint stripper containers and other flammable material from area. Allow fumes to disperse at least 15 minutes before welding or heating.

Avoid Heating Near Pressurized Fluid Lines

ˇ Flammable spray can be generated by

heating near pressurized fluid lines,

resulting in severe burns to yourself and bystanders. Do not heat by welding, soldering, or using a torch near pressurized fluid lines or other flammable materials. Pressurized lines can be accidentally cut when heat goes beyond the immediate flame area.

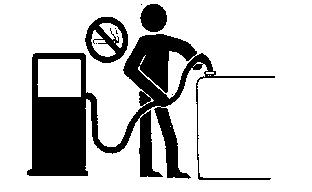

Handle Fuel Safely Avoid Fires

ˇ Handle fuel with care: it is highly flammable. Do not refuel the machine while smoking or when near open flame or sparks.

ˇ Always stop engine before refueling machine. Fill fuel tank outdoors.

ˇ Prevent fires by keeping machine clean of accumulated trash, grease, and debris. Always clean up spilled fuel.

Prepare For Emergencies

Keep a first aid kit and fire extinguisher

handy.

Keep emergency numbers for doctors, ambulance service, hospital, and fire department near your telephone.

Prevent Fires

ˇ Never remove fuel cap, or add fuel with engine running or hot. Allow engine to cool for several minutes.

ˇ Never store equipment with fuel in the tank inside a building where fumes may reach an open flame or spark.

ˇ Allow engine to cool before storing in any enclosure.

ˇ To reduce fire hazard, keep engine free of grass, leaves, or excessive grease.

ˇ Do not run engine in a closed building without adequate ventilation.

Roll-Over Protective Structure (ROPS)

ˇ Use a seat belt when operating with roll-over protective structure (ROPS) to minimize chance of injury from an accident such as an overturn.

ˇ Do not use a seat belt if operating without a ROPS.

ˇ A roll-over may place severe stress on the ROPS structure. Therefore, replace if structural members have been bent, buckled or otherwise damaged.

ˇ Under no circumstances modify structural members of ROPS by welding on additional parts, drilling holes, grinding, etc. Disregarding this instruction can affect the rigidity of the ROPS.

ˇ Use non-spill battery vent caps to prevent injury from spilled battery acid should the machine overturn and be supported upside-down by the ROPS. See your John Deere distributor.

ˇ All parts must be installed correctly if the ROPS is loosened or removed for any reason. Tighten mounting bolts to correct torque.

Keep Rops Installed Properly

ˇ Make certain all parts are reinstalled correctly if the roll-over protective structure (ROPS) is

loosened or removed for any reason. Tighten

mounting bolts to proper torque.

ˇ The protection offered by ROPS will be impaired if ROPS is subjected to structural damage, is involved in an overturn incident, or is in any way altered by welding, bending, drilling, or cutting. A damaged ROPS should be replaced, not reused.

Avoid Injury From Moving Parts

ˇ Keep hands, feet, and clothing away from power-driven parts.

ˇ Never clean, lubricate or adjust machine while it is running.

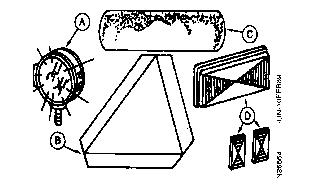

Use Safety Lights And Devices

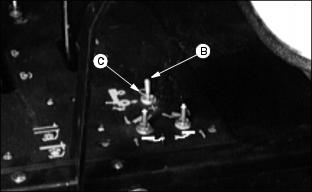

B - Slow Moving Vehicle Emblem

ˇ When transporting your machine on a road or highway at night or during the day, use necessary safety lights. Check local governmental regulations. A safety lighting kit is available from your John Deere dealer.

ˇ Keep safety items in good condition. Replace missing or damaged items.

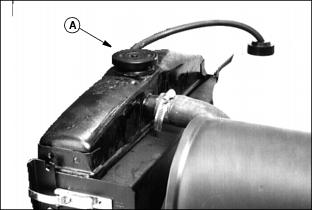

Support Raised Fuel Tank

IMPORTANT: Avoid damage! After closing fuel tank, replace air intake hose in hole in fuel tank cover. |

Service Cooling System Safely

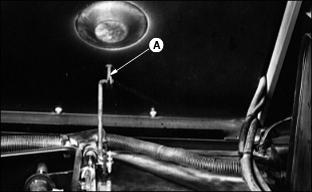

Do not remove radiator cap (A) when engine is hot.

Shut the engine off and wait until it cools.

Then turn the cap slowly to the first stop to relieve pressure before removing it completely.

Service Mower Safely

Before servicing, adjusting, or lubricating machine:

ˇ Shut off engine. Remove key.

ˇ THEN WAIT until all moving parts have stopped.

Hood and fuel tank are heavy. Handle weight safely.

Before working on engine, let it cool. Hot engine parts can burn skin on contact.

Use a long-handled brush when applying reel-sharpening compound.

Keep feet and hands away from cutting units when making adjustments.

Always wear gloves when manually rotating reel.

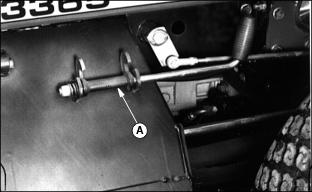

Transport latches (A) must be engaged before working on or around raised cutting units, one on each side of machine.

Operate with adequate ventilation

Turn valve counterclockwise to open.