Introduction

Safety Signs

Controls

Operating

Replacement Parts

Service Machine Safely

Service Intervals

Service Lubrication

Alternative And Synthetic Lubricants

Traction Unit Hydrostatic Transaxle/Hydraulic System

Checking Hydraulic Reservoir Oil Level

Checking Transmission/Hydraulic Oil Level

Service Engine

Service Transmission

Service Cutting Units

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

CopyrightŠ Deere & Company

Service Lubrication

Grease

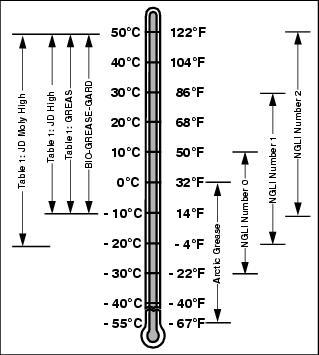

Use grease based on the expected air temperature range during the service interval.

The following greases are preferred:

ˇ John Deere Moly High Temperature EP Grease.

ˇ John Deere High Temperature EP Grease.

Other greases may be used are:

ˇ SAE Multipurpose EP Grease with 3 to 5 percent molybdenum disulfide.

ˇ Greases meeting Military Specification MIL-G-10924C may be used as arctic grease.

Hydrostatic Drive Oil

Use oil viscosity based on the expected air temperature range during the period between oil changes.

The following oils are preferred:

ˇ John Deere Low Viscosity HY-GARDŽ

Other oils may be used if they meet one of the following:

Service Lubrication

ˇ John Deere Standard JDM J20C

ˇ John Deere Standard JDM J20D

Alternative And Synthetic Lubricants

Conditions in certain geographical areas may require lubricant recommendations different from those printed in this operator's manual.

Some John Deere lubricants may not be available in your location. Consult your John Deere dealer to obtain information and recommendations.

Synthetic lubricants may be used if they meet the performance requirements as shown in this operator's manual.

Mower Hydraulic Oil

Use John Deere HY-GARDŽ Transmission and Hydraulic Oil or an equivalent oil meeting John Deere J20C specifications.

Traction Unit Hydrostatic Transaxle/Hydraulic System

Use John Deere HY-GARD Transmission and Hydraulic Oil or an equivalent oil meeting John Deere J20C specifications.

Cutting Unit Gear Case Grease

John Deere Cotton Picker Spindle Grease is recommended for cutting unit gear case.

If other grease is used, us e SAE Multipurpose Grease meeting NLGI Consistency Number 00.

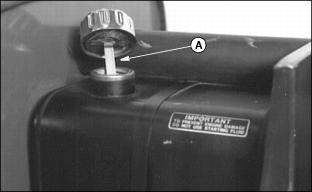

Checking Hydraulic Reservoir Oil Level

Check mower hydraulic reservoir dipstick (A). If oil level is not to FULL mark, add John Deere HY-GARD transmission and hydraulic oil. See Mower Hydraulic Oil in this section. Reservoir capacity is 26.5 L (7 gal).

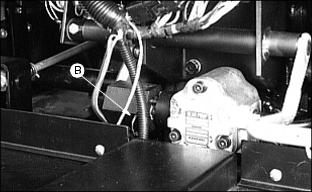

Checking Transmission/Hydraulic Oil Level

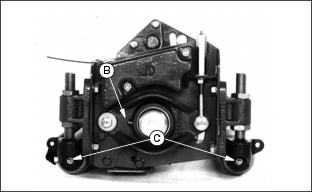

Check hydrostatic transaxle dipstick (B). If oil level is low, add John Deere HY-GARD Transmission/Hydraulic Oil.

See Hydrostatic Drive Oil in this section. Reservoir capacity is 18.9 L (5 gal).

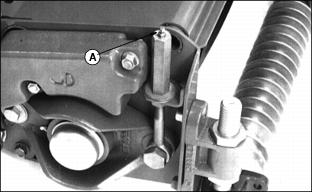

Grease Locations

Perform each lubrication illustrated in this section.

Clean grease fittings before lubricating.

Replace lost or broken fittings immediately.

NOTE: DO NOT over lubricate. Excess grease could fall from mower during operation.

IMPORTANT: Avoid damage! After operating and washing machine, grease rollers to flush contaminants from bearings. |

ˇ Grease adjusters (A) on each end of cutting units.

ˇ Grease reel bearing (B) on each cutting unit.

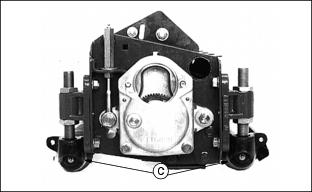

ˇ Grease rollers (C) on front and rear of cutting units.

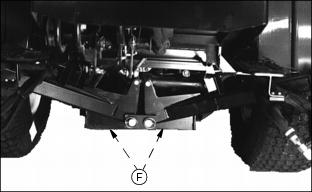

Grease Locations (Continued)

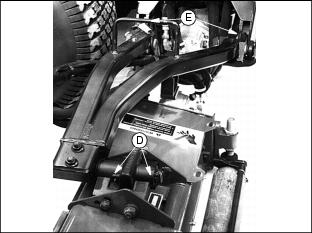

ˇ Grease cutting unit pivot pins (D) on each cutting unit and wing lift arm pivot pins (E) for both right and left wings.

NOTE: Left front tire removed for photo purposes ONLY.

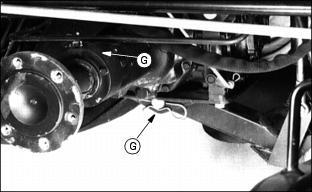

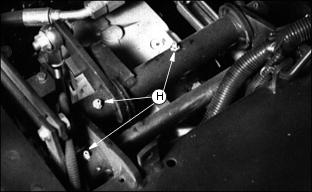

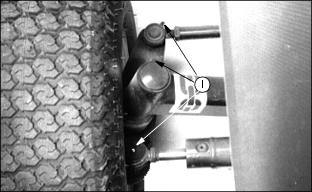

Grease Locations (Continued)

ˇ Grease lift and control links (H).

ˇ Grease rear axles and cylinders (I).

ˇ Grease brake and hydraulic pedals.

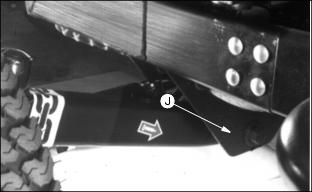

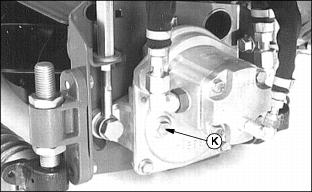

Grease Locations (Continued)

ˇ Pack gear case to fill plug (K) with John Deere Cotton Picker Spindle Grease or other SAE Multipurpose Grease meeting NLGI Consistency Number 00. See Cutting Unit Gear Case Grease in this section.