Introduction

Safety Signs

Controls

Operating Machine

Operating Mower

Replacement Parts

Service Machine Safely

Service Intervals

Service Lubrication

Service Engine

Changing Engine Oil And Filter

Checking Air Restriction Indicator

Cleaning Fuel Filter Sediment Bowl

Service Hydraulics/Transmission

Service Cutting Units

Service Electrical

Service Miscellaneous

Troubleshooting

Storing Vehicle

Assembly

Specifications

Warranty

John Deere Quality Statement

Copyright© Deere & Company

Service Engine

Avoid Fumes

· If it is necessary to run an engine in an enclosed area, use an exhaust pipe extension to remove the fumes. |

Engine Oil

Use oil viscosity based on the expected air temperature range during the period between oil changes.

The following oil is preferred:

The following oils are also recommended:

· John Deere TORQ-GARD SUPREME®

Other oils may be used if they meet one of the following:

· API Service Classification CE

· API Service Classification CD

If John Deere PLUS-50 engine oil and a John Deere oil filter are used, the oil and filter service interval may be extended by 50 hours.

If diesel fuel exceeding 0.5% sulfur content is used, reduce the service interval for engine oil and filter by 50%.

Oils meeting Military Specification MIL-L-46167B may be used as arctic oils.

Checking Engine Oil Level

NOTE: Check oil twice a day if engine is run over 4 hours a day.

3. Check the engine oil when oil is cold.

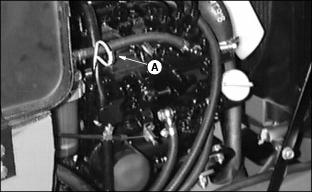

5. Clean around dipstick. Remove dipstick (A).

7. Remove dipstick. Check oil level on dipstick.

8. Oil must be between ADD and FULL marks.

9. If oil level is low, add oil to bring oil level no higher than FULL mark on dipstick. (See Engine Oil in this section for correct oil.)

10. Install dipstick. Lower the hood.

11. If oil level is above full mark, drain to the proper level. Determine cause of over full condition and correct.

Changing Engine Oil And Filter

NOTE: Change engine oil after the first 5 hours of break-in operation.

1. Run engine to warm the oil.

2. Park mower on level surface.

3. Stop engine, lock park brake, and remove ignition key.

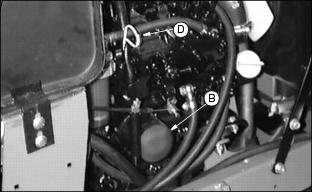

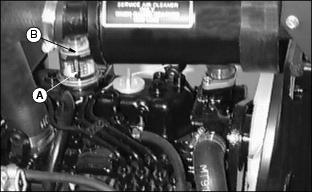

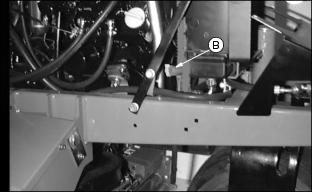

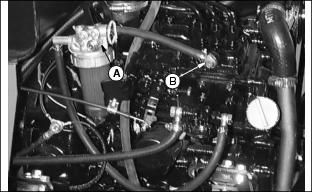

4. Remove drain plug (A) to drain oil.

5. Remove oil filter (B). Turn filter counterclockwise to remove.

6. Apply a film of clean engine oil on seal of new filter.

7. Install filter. Turn filter until seal contacts mounting surface. Tighten 1/2-3/4 turn after gasket contact.

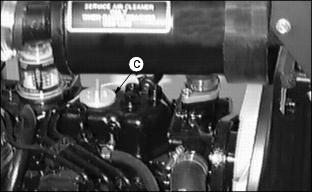

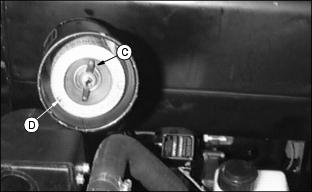

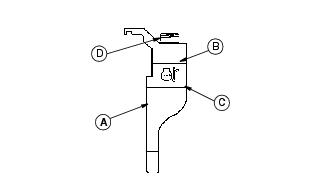

9. Remove filler cap (C). Add approximately 2.3 L (2.4 qt) of oil. (See Engine Oil in this section for correct oil.)

10. Remove dipstick (D) to check oil level.

11. Install and tighten filler cap.

12. Run engine at slow speed 2 minutes. Check for leaks around filter.

13. Stop engine and wait a couple of minutes. Check oil level. Add oil only to FULL mark on dipstick.

Cleaning Air Intake Screen

IMPORTANT: Avoid damage! Intake screen must be clear of dirt and debris to prevent engine from overheating and to allow good air intake for air cleaner. |

1. Stop engine, lock park brake, and remove key.

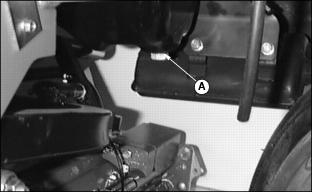

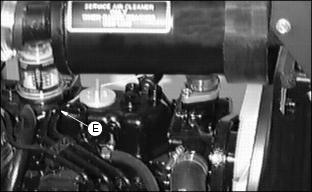

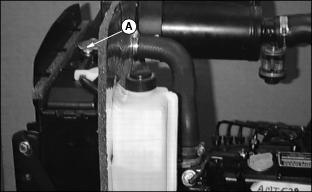

3. Remove air intake screen (A).

4. Clean air intake screen with brush or compressed air.

Checking Air Restriction Indicator

1. STOP engine, lock park brake, and remove key.

NOTE: Indicator will not signal correctly if indicator case has a break.

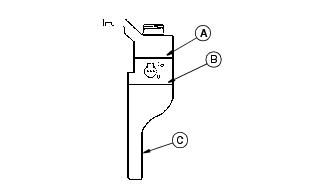

3. Check air restriction indicator: When yellow plunger (A) inside indicator reaches red line (B), air cleaner requires immediate service. (See Replacing Air Cleaner Element in this section.)

Replacing Air Cleaner Element

IMPORTANT: Avoid damage! DO NOT clean primary air cleaner element, replace it when air restriction indicator reaches red line. |

1. Stop engine, lock park brake, and remove key.

IMPORTANT: Avoid damage! DO NOT raise canister upward when removing primary and secondary elements. Dirt can fall into the intake manifold and could cause engine damage |

3. Pull air cleaner canister (A) from housing (B).

4. Remove and discard wing nut (C).

5. Remove and discard old primary element (D).

6. Install new primary element and wing nut.

7. Depress reset button (E) and then release to reset restriction indicator.

8. Start engine and allow it to run a minute at maximum speed.

9. Stop engine and check air restriction indicator. If indicator shows 500 mm (20 in.) vacuum, replace secondary element as explained in Step 10.

10. Remove primary element to install secondary element (F). Remove wing nut (G) to remove secondary element.

11. Install new secondary element and wing nut. Be sure wing nut is tight.

12. Install new primary element and wing nut. Be sure wing nut is tight.

Service Cooling System Safely

Engine Coolant

Use ethylene glycol base coolant. These coolants usually have labels stating "For Automobile and Light Duty Service." These products are also often labeled for use in aluminum engines. Check container label before using.

IMPORTANT: Avoid damage! To prevent engine damage due to overheating, DO NOT use pure antifreeze. DO NOT mix or add any other type additives to the cooling system. |

Mix approximately 50 percent antifreeze with 50 percent distilled or deionized water. This mixture will provide freeze protection to -37 degrees C (-34 degree F).

Certain geographical areas may require lower temperature protection. See the label on your antifreeze container or consult your John Deere distributor to obtain the latest information and recommendations.

The recommended antifreeze provides:

· Corrosion-resistant environment within the cooling system.

· Compatibility with cooling system hose and seal material.

· Protection during cold and hot weather operations.

Checking Coolant Level

· If engine is warm, coolant should be between lines (A) and (B) on coolant tank.

· If engine is cold, coolant should be above line (C).

3. Remove cap (D) to add coolant.

4. If coolant is low, add ethylene glycol (without stop-leak additive) antifreeze and distilled or deionized water in the ratio specified on the antifreeze container.

5. Install and tighten recovery tank cap.

6. Clean debris from air intake screen and radiator.

7. Check condition of hoses. Check for leaks or loose connections.

Draining Cooling System

1. Stop the engine and let cool.

3. Slowly remove radiator cap (A).

4. Open radiator petcock (B). Drain coolant into a bucket.

5. After all coolant has drained, close radiator petcock.

6. Flush cooling system. (See Flushing Cooling System in this section.)

Flushing Cooling System

Turn radiator cap using a thick rag or glove to protect your hand. |

1. Fill cooling system with clean water and John Deere Cooling System Cleaner, or John Deere Cooling System Quick Flush or an equivalent. Follow directions on the can.

2. Install and tighten radiator cap (A).

3. Start and run engine until it reaches operating temperature. Stop engine.

4. Open radiator petcock (B) and drain the cooling system immediately before rust and dirt settle.

Filling Cooling System

IMPORTANT: Avoid damage! To prevent engine damage due to overheating, DO NOT use pure antifreeze. DO NOT mix or add any other type additives to the cooling system. |

1. Fill cooling system. Mix approximately 50 percent antifreeze with 50 percent distilled or deionized water. This mixture will provide freeze protection to -37 degrees C (-34 degree F).

Certain geographical areas may require lower temperature protection. See the label on your antifreeze container or consult your John Deere distributor to obtain the latest information and recommendations.

John Deere Cooling System Sealer or its equivalent may be added to the radiator to seal leaks. Do not use any other additives in the cooling system.

2. Install and tighten radiator cap.

3. Run engine until it reaches operating temperature.

4. Stop engine. After engine cools, check coolant level in recovery tank (A). Level should be up to H mark (B) on tank when engine is hot or L mark (C) on tank when engine is cold. Remove cap (D) to add coolant if necessary.

5. Check condition of coolant system hoses. Install new hoses periodically. Tighten hose clamps regularly.

Checking Sediment Bowl

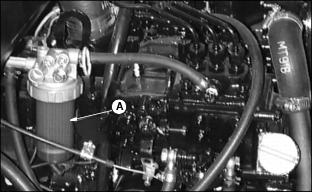

2. Check for water in sediment bowl (A): Orange ring will float on top of the water.

3. If necessary, clean bowl and replace filer. (See Cleaning Fuel Filter Sediment Bowl).

Cleaning Fuel Filter Sediment Bowl

2. Turn collar (A) to remove bowl and filter. Discard filter.

4. Install new filter and bowl.

Bleeding Fuel System

2. Loosen bleed screws (A) and (B).

3. Pump lever (C) until fuel flows from around screws.

4. Tighten screws when fuel flows free of bubbles.

6. If engine does not run smoothly, loosen three fuel line fittings (D) one at a time.