Introduction

Safety Signs

Controls

Operating Machine

Operating Mower

Replacement Parts

Service Machine Safely

Handling Waste Product And Chemicals

Avoid Injury From Contacting Blades

Service Intervals

Service Lubrication

Service Engine

Service Hydraulics/Transmission

Service Cutting Units

Service Electrical

Service Miscellaneous

Troubleshooting

Storing Vehicle

Assembly

Specifications

Warranty

John Deere Quality Statement

CopyrightŠ Deere & Company

Service Machine Safely

Practice Safe Maintenance

ˇ Understand service procedure before doing work. Keep area clean and dry.

ˇ Never lubricate, service, or adjust machine while it is moving. Keep safety devices in place and in working condition. Keep hardware tight.

ˇ To prevent them from getting caught, keep hands, feet, clothing, jewelry, and long hair away from any moving parts.

ˇ Before servicing machine, lower cutting units to the ground. Disengage all power and stop the engine. Lock park brake and remove the key. Wait until all moving parts have stopped. Let machine cool.

ˇ Securely support any machine elements that must be raised for service work.

ˇ Never run engine unless park brake is locked.

ˇ Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or debris.

ˇ Disconnect battery ground cable (-) before making adjustments on electrical systems or welding on machine.

ˇ Unauthorized modifications to the machine may impair its function and safety.

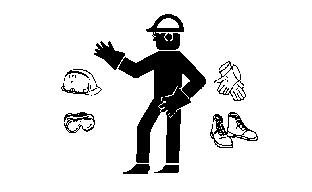

Wear Appropriate Clothing

ˇ Wear close fitting clothing and safety equipment appropriate for the job.

ˇ Loud noise can cause impairment or loss of hearing, wear a suitable protective device such as earplugs.

ˇ Do not wear radio or music headphones while servicing the machine. Safe service requires your full attention.

Handling Waste Product And Chemicals

ˇ Waste products, such as, used oil, fuel, coolant, brake fluid, and batteries, can harm the environment and people.

ˇ DO NOT use beverage containers for waste fluids-someone may drink from them.

ˇ See your local Recycling Center or John Deere distributor to learn how to recycle or get rid of waste products.

ˇ A Material Safety Data Sheet (MSDS) provides specific details on chemical products: physical and health hazards, safety procedures, and emergency response techniques. See your John Deere distributor for the MSDS on chemical products used with your machine.

Avoid High Pressure Fluids

ˇ Hydraulic hoses can fail due to physical damage, kinks, age, and exposure. Check hoses regularly. Replace damaged hoses.

ˇ Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure.

ˇ Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids.

ˇ If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A.

Prevent Fires

ˇ Never remove fuel cap, or add fuel with engine running or hot. Allow engine to cool for several minutes.

ˇ Never store equipment with fuel in the tank inside a building where fumes may reach an open flame or spark.

ˇ Allow engine to cool before storing in any enclosure.

ˇ To reduce fire hazard, keep engine free of grass, leaves, or excessive grease.

ˇ Do not run engine in a closed building without adequate ventilation.

Avoid Injury From Contacting Blades

BEFORE YOU DISMOUNT TO UNPLUG OR ADJUST CUTTING UNITS:

ˇ DISENGAGE reel drive by moving themow/transport lever to the Transport position.

ˇ LOWER cutting units to the ground.

ˇ Wait for reels and all moving parts to STOP.

BLOCKED OR STALLED CUTTING CYLINDERS:

ˇ Keep all parts of the body away from the cutting edges. Residual hydraulic pressure in the system can cause cutting cylinder rotation when the blockage is released.

ˇ Use a long-handled brush when applying reel-sharpening compound.

ˇ Keep hands, feet and clothing away from cutting units when engine is running.

ˇ Keep bystanders away from cutting units when adjusting or servicing.

ˇ Always wear gloves when manually rotating reel. Manually rotating one reel can cause another reel to rotate.