Introduction

Safety Signs

Controls

Operating Machine

Operating Mower

Replacement Parts

Service Machine Safely

Service Intervals

Service Lubrication

Service Engine

Service Hydraulics/Transmission

Replacing Hydraulic Oil Filter

Adjusting Transmission Neutral

Adjusting Ignition Interlock Switches

Service Cutting Units

Service Electrical

Service Miscellaneous

Troubleshooting

Storing Vehicle

Assembly

Specifications

Warranty

John Deere Quality Statement

Copyright© Deere & Company

Service Hydraulics/Transmission

Hydrostatic Drive Oil

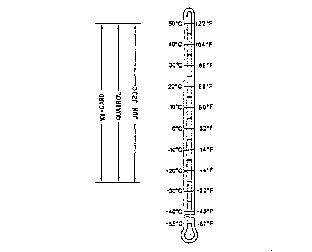

Use oil viscosity based on the expected air temperature range during the period between oil changes.

John Deere HY-GARD® Transmission/Hydraulic Oil is recommended.

Other oils may be used if they are QUATROL® oils or if they meet John Deere Standard JDM J20C.

Checking Hydraulic Oil Level

2. Lower cutting units to ground.

3. Stop engine and lock park brake.

4. Check oil level when oil is cold.

5. If oil level is low, add John Deere HY-GARD Transmission/Hydraulic Oil or an equivalent oil meeting John Deere J20C specifications.

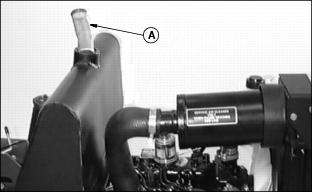

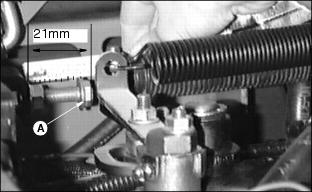

6. Fill to 0-25 mm (0-1 in.) above bottom of filler neck screen (A).

Changing Hydraulic Oil

NOTE: Change oil at 1000 hours or yearly, whichever comes first.

2. Remove bottom hose (A) off the hydraulic oil filter and drain oil. Use drain pan to catch oil.

4. Fill reservoir with approximately 16.6 L (4.4 gal) of oil. Use John Deere HY-GARD oil or an equivalent oil meeting John Deere specifications.

5. Start engine. Cycle hydraulic control for 1-2 minutes.

6. Stop engine and check oil level. Level should be 0-25 mm (0-1 in.) above bottom of screen.

Replacing Hydraulic Oil Filter

NOTE: Replace filter after first 50 hours of operation and every 1000 hours or yearly.

1. Stop engine. Lock the parking brake.

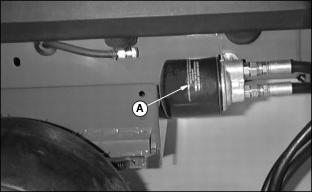

2. Turn hydraulic oil filter (A) counterclockwise to remove. Use drain pan to catch dripping oil.

3. Put a film of clean oil on seal of new filter.

4. Turn filter until seal contacts mounting surface. Tighten filter one full turn after gasket contact. A filter wrench may be required.

5. Start engine and check for leaks.

6. Stop engine and check oil level.

Adjusting Transmission Neutral

The machine may creep forward or backward while in neutral with engine running.

After engine has started, release parking brake and with directional speed control pedals centered. The machine should not move.

If movement is evident, neutral return mechanism is adjusted incorrectly.

1. Using a safe lifting device, raise greensmower so one drive wheel is off the floor.

2. Start engine and operate at slow idle.

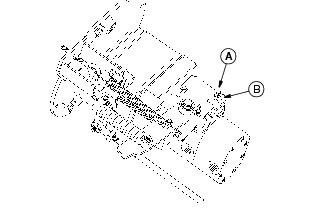

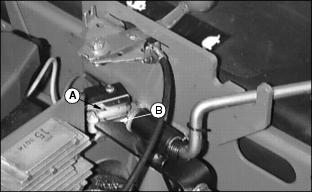

3. Loosen top nut (A) slightly and turn the eccentric cam (B) to stop wheel rotation.

· Clockwise stops forward creep.

· Counterclockwise stops reverse creep.

5. Re-check neutral setting by moving and releasing the forward and reverse pedals.

NOTE: After adjusting Transmission Neutral, Safety Interlock may need adjustment. (See Adjusting Ignition Interlock Switches in this section).

Adjusting Mowing Speed

Adjusting screw (A) determines mowing speed.

See Cutting Ratios below for correct adjustment.

Cutting Ratios

Adjusting Ignition Interlock Switches

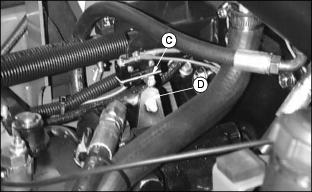

2. Move mow/transport lever to mow position.

3. Align switch (A) so that it is compressed against lever (B).

4. Put forward/reverse pedals in the NEUTRAL position.

5. Align switch (C) so it is compressed against top of shift lever (D).

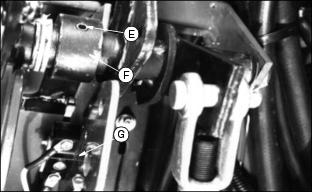

NOTE: Set screw (E), hub (F), and switch (G) are located under right side of platform.

8. Align switch hub (F) so it compresses switch (G).

10. Check adjustment by performing Tests in Operating The Machine section.