Specifications

Engine

Model

|

Yanmar

|

Engine Model Number

|

3TNE68

|

Fuel

|

Diesel

|

Horsepower

|

13.4 kW (18 hp)

|

Cylinders

|

3

|

Cycle

|

4

|

Displacement

|

585 cm3 (35.7 cu in.)

|

Speed (fast idle)

|

2975 75 rpm

|

Speed (low idle)

|

1400 75 rpm

|

Pressurized Lubrication

|

Standard

|

Oil Filter

|

Full Flow Filter

|

Air Cleaner

|

Semi-Cyclone

Dry Type Dual Stage

|

Cooling System

|

Liquid-cooled

|

Electrical System

Type

|

Flywheel, Alternator

|

Capacity

|

16 Amp. Reg.

|

Battery

|

BCI Group, 22F

|

Battery Voltage

|

12 Volts

|

Battery Reserve Capacity

at 25 Amp

|

68 Minutes

|

Battery Cold Cranking Amps at 0° F

|

490 Amps

|

Vehicle Specifications

Wheels and Tires

|

18 x 9.50-8.00 2 ply, Smooth or Turf Tread

|

Brakes

Dual

|

Single Pedal,

2 Wheel Disk Brakes

15.2 cm (6 in.) Dia.

|

Mowing Speed

|

6.4 km/h (0-4 mph)

|

Transport Speed

|

13.7 km/h (0-8.5 mph)

|

Reverse Speed

|

4.8 km/h (0-3 mph)

|

Fuel Tank Capacity (Total)

|

37.9 L (10 gal)

|

Muffler

|

Horizontal Discharge

Below Frame

|

Hydrostatic and

Reel Drive System (Total)

|

22.7 L (6.6 gal)

|

Hydraulic Reservoir Capacity (Only)

|

16.6 L (4.4 gal)

|

Engine Oil

|

2.3 L (2.4 qt)

|

Cooling System Capacity

|

4.0 L (4.2 qt)

|

Transaxle, Reel Drive

Drive Wheels

|

Front

|

Traction Drive

|

Hydrostatic, 2 Pedal Control

|

Reel Drive

|

Hydraulic

|

Pumps:

Double Gear

Piston

|

Mow, Lift and Steering

Traction

|

Reel Control Valves

|

Electro Hydraulic,

One Valve Reel On-Off,

and One Valve Raise-Lower

|

Filtration

|

10 Micron

|

Mower Lift

|

Cylinder for Front 2 Units,

Cylinder for Center Unit

|

Mower

Number of Cutting Units

|

3

|

Size

|

22 in. (55.9 cm) Floating Standard Lateral, Fore, and Aft

|

Backlapping

|

Optional-Variable Speed Adjustment Capability

|

Clip Frequency

|

5.6 mm (.22 in.)

6.4 km/h (4.0 mph)

|

Front Rollers

|

Optional-Smooth or Grooved

|

Reel Diameter

|

12.7 cm (5 in.)

|

Bed Knife Adjustment

|

Reel-to-bed Knife

|

Height of Cut

|

2.4 to 19 mm (3/32 to 3/4 in.)

|

Number of Blades

|

9

|

Cutting Unit Drive

|

Direct Hydraulic Motor

|

Weights and Dimensions

Wheel Base

|

1.30 m (4 ft 3 in.)

|

Tread Width

|

1.02 m (3 ft 4 in.)

|

Mowing Position Width

|

1.57 m (5 ft 2 in.)

|

Turning Radius,

Uncut Circle

|

.60 m (23.6 in.)

|

Empty Weight

(less attachments)

|

467 kg (1030 lb)

|

Cutting Unit Weight

|

34 kg (74 lb)

|

Overall Length

|

2.26 m (7 ft 5 in.)

|

Overall Width

|

1.83 m (6 ft)

|

Overall Height

|

1.26 m (4 ft 2 in.)

|

Sound Rating:

Low Idle

High Idle

|

68 dB(A)

88 dB(A)

|

Recommended Lubricants

Fuel

|

Diesel

|

Engine Oil

|

John Deere PLUS-50TM

|

Engine Coolant

|

Ethylene Glycol Base

|

Transmission Oil

|

John Deere HY-GARD®

|

Grease

|

John Deere MOLY HIGH TEMPERATURE EP GREASE

|

|

John Deere HIGH TEMPERATURE EP GREASE

|

|

John Deere GREASE GARDTM

|

(Specifications and design subject to change without notice.)

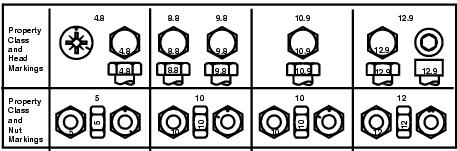

Metric Bolt and Cap Screw Torque Values

|

Class 4.8

|

Class 8.8 or 9.8

|

|

Lubricateda

|

Drya

|

Lubricateda

|

Drya

|

Size

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

M6

|

48

|

3.5

|

6

|

4.5

|

9

|

6.5

|

11

|

8.5

|

M8

|

12

|

8.5

|

15

|

11

|

22

|

16

|

28

|

20

|

M10

|

23

|

17

|

29

|

21

|

43

|

32

|

55

|

40

|

M12

|

40

|

29

|

50

|

37

|

75

|

55

|

95

|

70

|

M14

|

63

|

47

|

80

|

60

|

120

|

88

|

150

|

110

|

M16

|

100

|

73

|

125

|

92

|

190

|

140

|

240

|

175

|

M18

|

135

|

100

|

175

|

125

|

260

|

195

|

330

|

250

|

M20

|

190

|

140

|

240

|

180

|

375

|

275

|

475

|

350

|

M22

|

260

|

190

|

330

|

250

|

510

|

375

|

650

|

475

|

M24

|

330

|

250

|

425

|

310

|

650

|

475

|

825

|

600

|

M27

|

490

|

360

|

625

|

450

|

950

|

700

|

1200

|

875

|

M30

|

675

|

490

|

850

|

625

|

1300

|

950

|

1650

|

1200

|

M33

|

900

|

675

|

1150

|

850

|

1750

|

1300

|

2200

|

1650

|

M36

|

1150

|

850

|

1450

|

1075

|

2250

|

1650

|

2850

|

2100

|

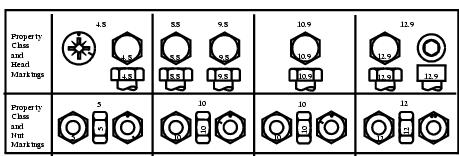

Metric Bolt and Cap Screw Torque Values (Continued)

|

Class 10.9

|

Class 12.9

|

|

Lubricateda

|

Drya

|

Lubricateda

|

Drya

|

Size

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

M6

|

13

|

9.5

|

17

|

12

|

15

|

11.5

|

19

|

14.5

|

M8

|

32

|

24

|

40

|

30

|

37

|

28

|

47

|

35

|

M10

|

63

|

47

|

80

|

60

|

75

|

55

|

95

|

70

|

M12

|

110

|

80

|

140

|

105

|

130

|

95

|

165

|

120

|

M14

|

175

|

130

|

225

|

165

|

205

|

150

|

260

|

109

|

M16

|

275

|

200

|

350

|

225

|

320

|

240

|

400

|

300

|

M18

|

375

|

275

|

475

|

350

|

440

|

325

|

560

|

410

|

M20

|

530

|

400

|

675

|

500

|

625

|

460

|

800

|

580

|

M22

|

725

|

540

|

925

|

675

|

850

|

625

|

1075

|

800

|

M24

|

925

|

675

|

1150

|

850

|

1075

|

800

|

1350

|

1000

|

M27

|

1350

|

1000

|

1700

|

1250

|

1600

|

1150

|

2000

|

1500

|

M30

|

1850

|

1350

|

2300

|

1700

|

2150

|

1600

|

2700

|

2000

|

M33

|

2500

|

1850

|

3150

|

2350

|

2900

|

2150

|

3700

|

2750

|

M36

|

3200

|

2350

|

4050

|

3000

|

3750

|

2750

|

4750

|

3500

|

Metric Bolt and Cap Screw Torque Values (Continued)

DO NOT use these values if a different torque value or tightening procedure is given for a specific application. Torque values listed are for general use only. Check tightness of fasteners periodically.

Shear bolts are designed to fail under predetermined loads. Always replace shear bolts with identical grade.

Fasteners should be replaced with the same or higher grade. If higher grade fasteners are used, these should only be tightened to the strength of the original. Make sure fasteners threads are clean and that you properly start thread engagement. This will prevent them from failing when tightening.

Tighten plastic insert or crimped steel-type lock nuts to approximately 50 percent of the dry torque shown in the chart, applied to the nut, not to the bolt head. Tighten toothed or serrated-type lock nuts to the full torque value.

a "Lubricated" means coated with a lubricant such as engine oil, or fasteners with phosphate and oil coatings. "Dry" means plain or zinc plated without any lubrication.

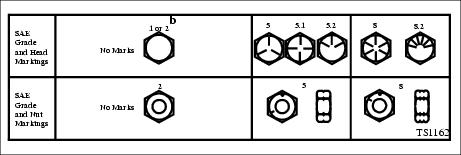

b Grade 2 applies for hex cap screws (not hex bolts) up to 152 mm (6-in) long. Grade 1 applies for hex cap screws over 152 mm (6-in) long, and for all other types of bolts and screws of any length.

Unified Inch Bolt and Cap Screw Torque Values

|

Grade 1

|

Grade 2b

|

|

Lubricateda

|

Drya

|

Lubricateda

|

Drya

|

SIZE

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

1/4

|

3.7

|

2.8

|

4.7

|

3.5

|

6

|

4.5

|

7.5

|

5.5

|

5/16

|

7.7

|

5.5

|

10

|

7

|

12

|

9

|

15

|

11

|

3/8

|

14

|

10

|

17

|

13

|

22

|

16

|

27

|

20

|

7/16

|

22

|

16

|

28

|

20

|

35

|

26

|

44

|

32

|

1/2

|

33

|

25

|

42

|

31

|

53

|

39

|

67

|

50

|

9/16

|

48

|

36

|

60

|

45

|

75

|

56

|

95

|

70

|

5/8

|

67

|

50

|

85

|

62

|

105

|

78

|

135

|

100

|

3/4

|

120

|

87

|

150

|

110

|

190

|

140

|

240

|

175

|

7/8

|

190

|

140

|

240

|

175

|

190

|

140

|

240

|

175

|

1

|

290

|

210

|

360

|

270

|

290

|

210

|

360

|

270

|

1-1/8

|

470

|

300

|

510

|

375

|

470

|

300

|

510

|

375

|

1-1/4

|

570

|

425

|

725

|

530

|

570

|

425

|

725

|

530

|

1-3/8

|

750

|

550

|

950

|

700

|

750

|

550

|

950

|

700

|

1-1/2

|

1000

|

725

|

1250

|

925

|

990

|

725

|

1250

|

930

|

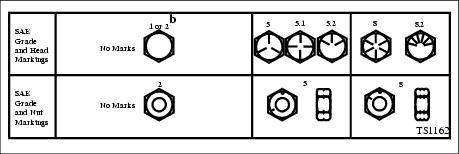

Unified Inch Bolt and Cap Screw Torque Values (Continued)

|

Grade 5, 5.1 or 5.2

|

Grade 8 or 8.2

|

|

Lubricateda

|

Drya

|

Lubricateda

|

Drya

|

SIZE

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

N·m

|

lb-ft

|

1/4

|

9.5

|

7

|

12

|

9

|

13.5

|

10

|

17

|

12.5

|

5/16

|

20

|

15

|

25

|

18

|

28

|

21

|

35

|

26

|

3/8

|

35

|

26

|

44

|

33

|

50

|

36

|

63

|

46

|

7/16

|

55

|

41

|

70

|

52

|

80

|

58

|

100

|

75

|

1/2

|

85

|

63

|

110

|

80

|

120

|

90

|

150

|

115

|

9/16

|

125

|

90

|

155

|

115

|

175

|

130

|

225

|

160

|

5/8

|

170

|

125

|

215

|

160

|

215

|

160

|

300

|

225

|

3/4

|

300

|

225

|

375

|

280

|

425

|

310

|

550

|

400

|

7/8

|

490

|

360

|

625

|

450

|

700

|

500

|

875

|

650

|

1

|

725

|

540

|

925

|

675

|

1050

|

750

|

1300

|

975

|

1-1/8

|

900

|

675

|

1150

|

850

|

1450

|

1075

|

1850

|

1350

|

1-1/4

|

1300

|

950

|

1650

|

1200

|

2050

|

1500

|

2600

|

1950

|

1-3/8

|

1700

|

1250

|

2150

|

1550

|

2700

|

2000

|

3400

|

2550

|

1-1/2

|

2250

|

1650

|

2850

|

2100

|

3600

|

2650

|

4550

|

3350

|

Unified Inch Bolt and Cap Screw Torque Values (Continued)

DO NOT use these values if a different torque value or tightening procedure is given for a specific application. Torque values listed are for general use only. Check tightness of fasteners periodically.

Shear bolts are designed to fail under predetermined loads. Always replace shear bolts with identical grade.

Fasteners should be replaced with the same or higher grade. If higher grade fasteners are used, these should only be tightened to the strength of the original. Make sure fasteners threads are clean and that you properly start thread engagement. This will prevent them from failing when tightening. Tighten plastic insert or crimped steel-type lock nuts to approximately 50 percent of the dry torque shown in the chart, applied to the nut, not to the bolt head.

Tighten toothed or serrated-type lock nuts to the full torque value.

a "Lubricated" means coated with a lubricant such as engine oil, or fasteners with phosphate and oil coatings. "Dry" means plain or zinc plated without any lubrication.

b Grade 2 applies for hex cap screws (not hex bolts) up to 152 mm (6-in.) long. Grade 1 applies for hex cap screws over 152 mm (6-in.) long, and for all other types of bolts and screws of any length.

|