2243 Diesel Professional Greensmower

Rotating Blades Are Dangerous - Protect Others And Prevent Accidents

Using Hydrostatic Transmission

Avoid Damage To Plastic And Painted Surfaces

CopyrightŠ Deere & Company

Introduction

Safety Signs

Controls

Operating Machine

Operating Mower

Replacement Parts

Service Machine Safely

Service Intervals

Service Lubrication

Service Engine

Service Hydraulics/Transmission

Service Cutting Units

Service Electrical

Service Miscellaneous

Troubleshooting

Storing Vehicle

Assembly

Specifications

Warranty

John Deere Quality Statement

Operating Machine

Operate Safely

ˇ Check brake action before you operate. Adjust or service brakes as necessary.

ˇ Inspect machine before you operate. Be sure hardware is tight. Repair or replace damaged, badly worn, or missing parts. Be sure guards and shields are in good condition and fastened in place. Make any necessary adjustments before you operate.

ˇ Clear work area of objects that might be thrown. Keep people and pets out of the work area. Stop machine if anyone enters the area.

ˇ If you hit an object, stop the machine and inspect it. Make repairs before you operate. Keep machine and attachments properly maintained and in good working order.

ˇ DO NOT leave machine unattended when it is running.

ˇ Only operate during daylight or with good artificial light.

ˇ Be careful of traffic when operating near or crossing roadways.

ˇ Do not wear radio or music headphones while operating the machine. Safe operation requires your full attention.

Mount And Dismount Safely

ˇ Do not step on pedals when mounting or dismounting.

ˇ Keep step area and platform clean.

ˇ Stop machine, move Mow/Transport lever to transport position, lower cutting units to the ground, lock park brake, stop engine, remove key, and wait for all moving parts to stop before dismounting.

Park Safely

ˇ Stop machine on a level surface, not on a slope.

ˇ Disengage the cutting units.

ˇ Lower the cutting units to the ground.

ˇ Before you leave the operator's seat, wait for engine and all moving parts to STOP.

Keep Riders Off

ˇ Only allow the operator on the machine. Keep riders off.

ˇ Riders on the machine or attachment may be struck by foreign objects or thrown off the

machine causing serious injury.

ˇ Riders obstruct the operator's view resulting in the machine being operated in an unsafe manner.

Rotating Blades Are Dangerous - Protect Others And Prevent Accidents

ˇ Turn machine off if another person enters the mowing area.

ˇ Use extra care when you come to blind corners, shrubs, trees, or other objects that may block your vision.

ˇ DO NOT let untrained person operate the machine.

ˇ DO NOT carry or let others ride on machine.

HELP PREVENT SERIOUS OR FATAL ACCIDENTS:

ˇ Be alert at all times, drive forward carefully. People can move quickly into the mowing area before you know it.

ˇ DO NOT operate machine if you are under the influence of drugs or alcohol.

ˇ Back carefully. Shut off cutting units and look behind the machine carefully before you back up.

ˇ Shut off cutting units when you are not mowing.

ˇ Stop engine and wait for reels to stop turning before making any adjustments to the cutting units.

ˇ Keep hands and feet away from cutting units while machine is running.

Avoid Tipping

ˇ DO NOT drive where machine could slip or tip.

ˇ Stay alert for holes and other hidden hazards in the terrain.

ˇ Slow down before you make a sharp turn or operate on a slope.

ˇ Drive up and down a hill - not across. Be careful when you change direction on a slope.

ˇ DO NOT try to stabilize the machine by putting your foot on the ground.

Operator Training Required

ˇ Study operation section of this manual before operating the machine.

ˇ Operate machine in an open, unobstructed area under the direction of an experienced operator.

ˇ Learn the use of all controls.

ˇ Operator experience is required to learn the moving, stopping, turning and other operating characteristics of the machine.

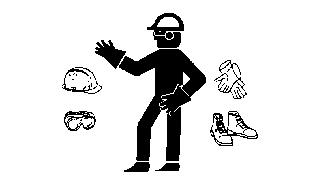

Wear Appropriate Clothing

ˇ Wear close fitting clothing and safety equipment appropriate for the job.

ˇ Loud noise can cause impairment or loss of hearing, wear a suitable protective device such as earplugs.

ˇ Do not wear radio or music headphones while operating the machine. Safe operation requires your full attention.

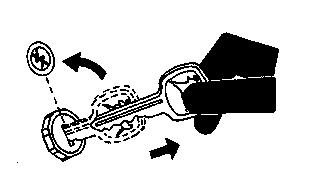

Check Wheel Bolts

ˇ A serious accident could occur causing serious injury if wheel bolts are not tight.

ˇ Check wheel bolt tightness often during the first 100 hours of operation.

Transport Safely

ˇ Use safety lights and devices. Slow moving machines when driven on public roads are hard to see, especially at night. Avoid personal injury or death resulting from a collision with a vehicle.

ˇ Flashing warning lights are recommended whenever driving on public roads to increase visibility. Extra flashing warning lights may need to be installed.

Avoid Neutral Creep

ˇ The machine may creep forward or backward while in neutral with engine running.

ˇ After engine has started, release parking brake and with directional speed control speed pedals centered, machine should not move.

ˇ If movement is evident, neutral return mechanism is adjusted incorrectly. (See Adjusting Transmission Neutral in Service - Hydraulics/Transmission section).

Avoid High Pressure Fluids

ˇ Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure.

ˇ Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids.

ˇ If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A.

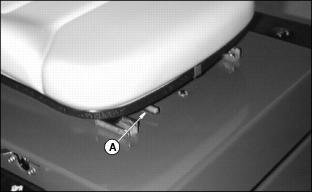

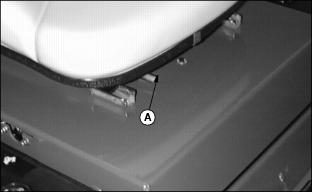

Adjusting Seat

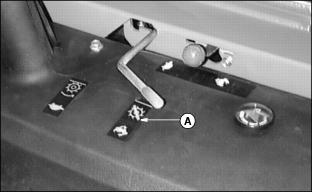

1. Move lever (A) to the left.

2. Slide seat forward or backward to desired position.

Tilt Steering Wheel

1. Loosen knobs (A) on each side of steering column.

2. Position wheel and tighten knobs.

Using Fuel Selector Valve

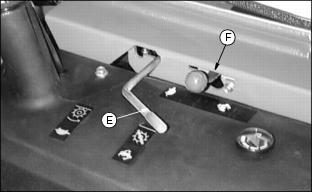

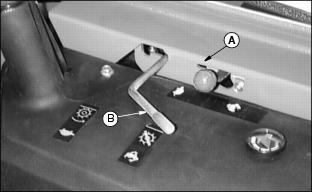

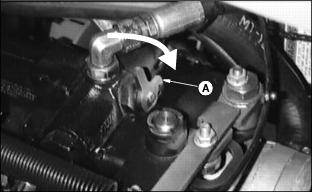

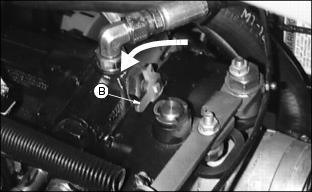

Use selector valve to select right fuel tank (A) or left fuel tank (B).

Using Fuel Shut-Off Valves

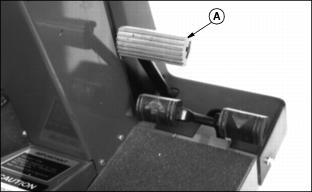

Each fuel tank is equipped with a fuel shut-off valve (A).

Turn valve to the right to close.

These valves should be closed if the machine is placed in extended storage.

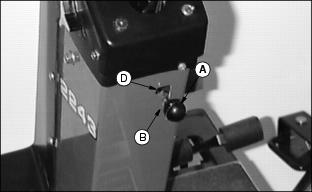

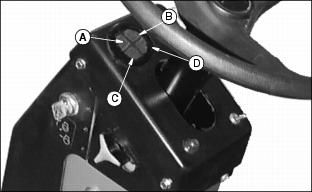

Using The Park Brake

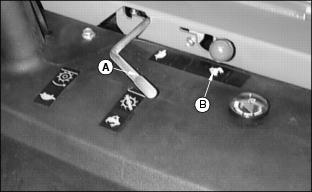

1. Move parking brake knob (A) into long slot (B).

3. Release pedal. Pedal should stay down.

NOTE: Forward and reverse pedals are operational when parking brake is locked.

1. Push down slightly and hold pedal.

2. Move parking brake knob up into short slot (D).

Indicator Lights

When key is in "START" position, all four indicator lights in module should come on.

The Hydraulic Oil Temperature, Engine Oil Pressure, and Engine Coolant Temperature lights should go out within 5 seconds.

The Battery Discharge Indicator should go out within 10 seconds. If not, move throttle lever to 3/4 position.

If indicator lights stay on longer than given time, or while engine is running, stop engine immediately. Find and correct problem.

Hydraulic Oil Temperature Indicator (A) will glow when hydraulic oil temperature is high. Stop engine immediately and let hydraulic oil temperature cool. Check oil level. Continued operation may cause higher temperatures resulting in damage.

Engine Oil Pressure Indicator (B) will glow when engine oil pressure is low. If lamp glows when engine is running, stop engine immediately. Check oil level. See your John Deere distributor.

Battery Discharge Indicator (C) will glow when alternator is not producing adequate current. Stop engine and determine cause.

Engine Coolant Temperature Indicator (D) will glow if temperature becomes excessive. Stop engine and determine cause.

Ignition Interlock Systems

For the starter to engage and the engine to run, the following conditions must be met simultaneously:

ˇ Operator on seat and/or parking brake locked.

ˇ Mow/transport lever in the TRANSPORT position.

ˇ Hydrostatic ground drive pedals in the NEUTRAL position.

If operator is mowing (mow/transport lever in mow and/or ground drive engaged) and the operator leaves the seat, the engine will stop.

If the operator has stopped mowing (mow/transport lever in transport) and leaves the seat with ground drive in neutral, but without the parking brake locked, the engine will stop.

Provision has been made to allow a single operator to service the reels. (See Service - Cutting Units section).

Starting The Engine

1. Open fuel shut-off valve for selected fuel tank.

2. Move seat lever (A) to the left. Slide seat forward or backward to most comfortable position.

3. Lock parking brake. Move parking brake knob (B) to lower slot (C) and push brake pedal down. Pedal should stay down.

NOTE: Forward and reverse pedals are operational when parking brake is locked.

5. If the air temperature is below 40°F, then the air preheat can be activated by holding the toggle switch (D) up for approximately 8-10 seconds. Engine preheat light, (glow plug), (E) will stay on until toggle switch is released.

NOTE: The mower has an ignition interlock switch. The engine will NOT start unless:

ˇ Operator is on seat or parking brake is locked.

ˇ Mow/transport lever is in the TRANSPORT position.

ˇ Hydrostatic ground drive pedals are in the NEUTRAL position.

6. Position mow/transport lever (E) in the TRANSPORT position.

7. Move throttle to half speed, position (F).

8. Turn key (G) to START position.

9. When engine starts, release key to RUN position.

Warming And Idling Engine

Run engine at half speed for 2 to 3 minutes.

The engine needs a large volume of air to keep cool. Keep radiator screens clean.

Avoid unnecessary engine idling.

Stopping The Engine

1. Move throttle lever down to SLOW position (A). Let engine idle before stopping.

2. Position mow/transport lever (B) to the TRANSPORT position and lower cutting units.

4. Turn key to the OFF position.

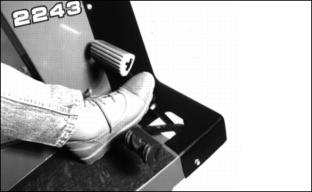

Emergency Stopping

Push hard on parking brake pedal (A).

Using Hydrostatic Transmission

2. Move mow/transport lever (A) to the TRANSPORT position.

3. Move throttle lever all the way forward to FAST position (B).

Slowly push speed control pedal (C) down. The farther the pedal is pushed down the faster the mower will travel.

Remove foot from pedal and pedal will return to the NEUTRAL position.

Forward travel speed is 0-13.7 km/h (0-8.5 mph).

Slowly push speed control pedal (D) down. The farther the pedal is pushed down, the faster the mower will travel.

Reverse travel speed is 0-4.8 km/h (0-3 mph).

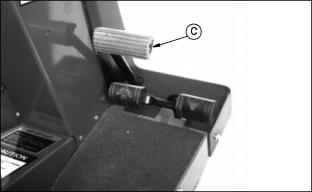

Using Free-Wheeling Lever

When you need to move the greensmower without starting the engine, use the free-wheeling lever.

1. Lift seat. (See Raising Seat in Service - Miscellaneous section).

2. Move lever (A) down to "free-wheeling" position.

4. Push or pull greensmower to desired location.

5. Before starting engine move the free-wheeling lever back to "run" position (B). Lever will not return to "run" position automatically.

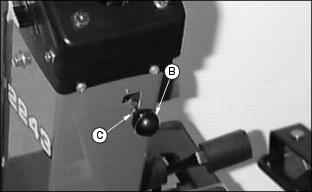

Using Hourmeter

ˇ The hourmeter (A) shows the number of hours the engine has run.

ˇ Service machine at recommended intervals and record hours and date.

Daily Operating Checklist

Testing Safety Systems

Use the following checkout procedure to check for normal operation of greensmower.

If there is a malfunction during one of these procedures, DO NOT operate greensmower. (See your John Deere distributor for service.)

Perform these tests in a clear open area. Keep bystanders away.

TEST 1

3. Move hydrostatic drive pedals to the NEUTRAL position.

4. Move mow/transport lever to mow (A).

5. Turn key to the "START" position. Engine must not crank.

6. Turn key to the "OFF" position.

7. Move mow/transport lever to transport (B).

8. Turn key to the "START" position. Engine must crank.

TEST 2

3. Move mow/transport lever to transport.

4. Move hydrostatic drive pedals out of NEUTRAL position.

5. Turn key to the "START" position. Engine must not crank.

TEST 3

1. Move mow/transport lever to transport (A).

3. Move hydrostatic drive pedals to the NEUTRAL position.

5. Turn key to the "START" position. Engine must not crank.

6. Turn key to the "OFF" position.

9. Turn key to the "START" position. Engine must crank.

TEST 4

1. Move mow/transport lever to transport (A).

3. Move hydrostatic drive pedals to the NEUTRAL position.

5. Turn key to the "START" position. Engine must not crank.

6. Turn key to the "OFF" position.

8. Turn key to the "START" position. Engine must crank.

Avoid Damage To Plastic And Painted Surfaces

ˇ Insect repellent spray may damage plastic and painted surfaces. Do not spray insect repellent near machine.

ˇ Be careful not to spill fuel on machine. Fuel may damage surface. Wipe up spilled fuel immediately.

Transporting The Greensmower

IMPORTANT: Avoid damage! NEVER TOW the greensmower. Damage to hydrostatic pump and transaxle will occur if towed. Transport machine on a trailer or truck. |

Use a heavy-duty trailer designed to carry 909 kg (2000 lb), or a truck to transport machine.

Lower the cutting units to the deck.

If the machine is transported facing forward, the hood should be secured to the machine at the front to avoid the hood opening accidentally during transport.

Fasten the machine with straps, chains, or cables.

The tie downs should be attached to slots provided under the operator's station in the main frame and in the rear wheel yoke.

When transporting the machine on a road or highway, use accessory lights and devices for adequate warning to operators of other vehicles. Check local, state, provincial, or federal laws.